2025 Top Vertical Packaging Machine Trends You Need to Know

As the packaging industry continues to evolve, the demand for efficient and innovative solutions becomes increasingly crucial. Among these, the vertical packaging machine stands out as a key player in enhancing productivity and sustainability. According to Dr. Emily Carter, a leading expert in packaging technology, "The future of packaging lies in automation and adaptability, and vertical packaging machines offer unparalleled flexibility to meet diverse market needs."

In the coming years, we can expect to see significant advancements in vertical packaging machines, including smarter automation, improved material handling, and eco-friendly designs. These innovations not only streamline the packaging process but also cater to the growing emphasis on sustainable practices in manufacturing. As Dr. Carter elaborates, "Vertical packaging machines are not just about filling and sealing; they are becoming an integral part of a holistic approach to packaging that prioritizes efficiency and environmental responsibility."

This article will delve into the top trends shaping the vertical packaging machine landscape for 2025, providing insights into how these developments will impact various industries and the future of packaging technology as a whole.

Emerging Technologies in Vertical Packaging Machines for 2025

As the packaging industry evolves, vertical packaging machines are set to undergo significant transformations in 2025, driven by emerging technologies that enhance efficiency and sustainability. One of the key trends is the integration of smart technology, allowing for real-time monitoring and data analysis during the packaging process. This advancement enables manufacturers to optimize production lines, reduce waste, and ensure consistent quality, resulting in higher operational efficiency.

Furthermore, automation and robotics are expected to play a crucial role in the development of vertical packaging machines. The implementation of advanced robotic arms can streamline tasks, such as loading and unloading of products, reducing manual labor and minimizing human error. Additionally, the adoption of artificial intelligence (AI) will lead to smarter machines that can adapt to varying production demands, thus increasing flexibility in manufacturing processes. These innovations not only enhance productivity but also promote a more sustainable approach by minimizing resource consumption and waste throughout the packaging lifecycle.

2025 Top Vertical Packaging Machine Trends You Need to Know

| Trend | Description | Impact | Technology Type |

|---|---|---|---|

| Smart Automation | Integration of AI and IoT for real-time monitoring and optimization of packaging processes. | Increased efficiency and reduced downtime. | AI, IoT |

| Sustainable Materials | Utilization of biodegradable and recyclable materials in packaging. | Reduced environmental impact and compliance with regulations. | Material Science |

| Flexible Packaging | Shift towards lightweight and versatile packaging formats. | Cost savings and improved product shelf life. | Polymer Technology |

| Digital Printing | Advancements in digital printing techniques for customized packaging. | Enhanced brand differentiation and reduced waste. | Digital Printing Tech |

| Data Analytics | Use of big data to analyze consumer preferences and optimize packaging. | Improved market adaptability and consumer satisfaction. | Big Data Analytics |

Sustainable Materials and Their Impact on Packaging Trends

As the packaging industry continues to evolve, the adoption of sustainable materials is becoming increasingly prominent in shaping vertical packaging machine trends. Sustainable materials, such as biodegradable plastics, recycled papers, and plant-based composites, are gaining traction as companies strive to reduce their environmental footprint. These materials not only cater to consumer demand for eco-friendly products but also align with corporate social responsibility goals, pushing manufacturers to innovate in their packaging solutions.

The impact of sustainable materials on packaging trends is profound. As manufacturers integrate these materials into their vertical packaging machines, they are compelled to rethink design and functionality to ensure that sustainability does not compromise performance. This includes the development of lighter packaging that minimizes waste, as well as machines that are capable of efficiently handling a variety of sustainable materials without sacrificing speed or quality. Additionally, the shift towards sustainability is prompting advances in packaging technology, such as improved barrier properties and sealing techniques, which help prolong shelf life while maintaining eco-friendliness. Ultimately, the commitment to sustainable materials is steering the entire packaging landscape towards a greener future.

Automation and Smart Features in Modern Vertical Packaging Machines

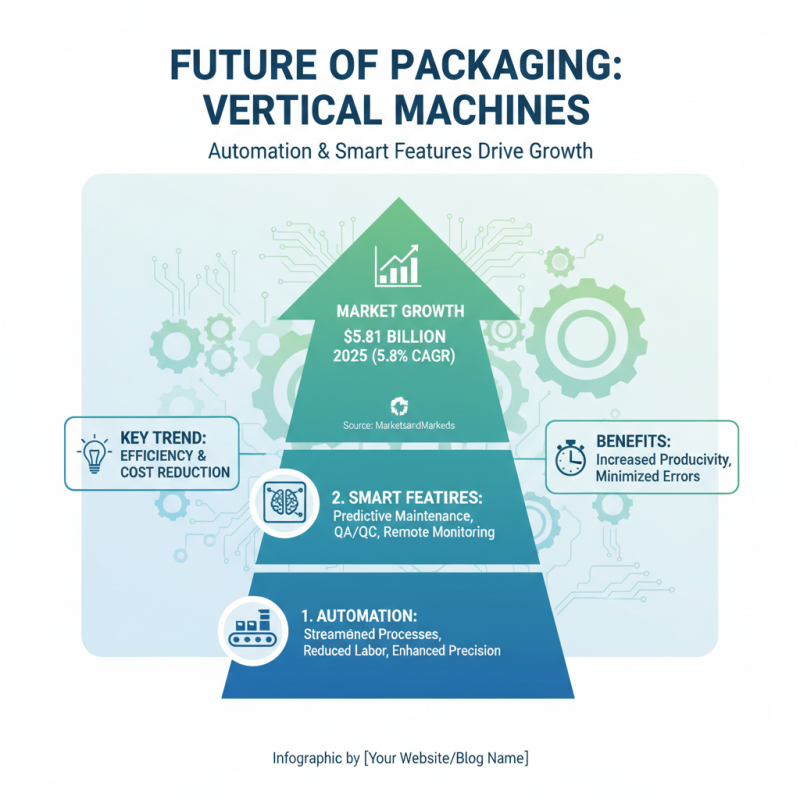

The landscape of vertical packaging machines is rapidly evolving, with automation and smart features taking center stage in modern designs. According to a report by MarketsandMarkets, the vertical packaging machinery market is projected to reach $5.81 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.8%. This growth is primarily driven by the increasing demand for efficient packaging solutions that enhance productivity and reduce operational costs. Automation has emerged as a critical trend, enabling manufacturers to streamline processes and minimize human intervention, which not only speeds up production but also improves precision.

The integration of smart technology into vertical packaging machines further enhances their capabilities. Systems equipped with IoT (Internet of Things) technology allow for real-time data monitoring and analytics, enabling manufacturers to optimize their production lines. According to a study by Grand View Research, the adoption of smart manufacturing solutions is expected to increase the efficiency of packaging operations by 30% over the next few years. These advancements in automation and smart features not only assist in achieving higher packaging speeds but also improve the quality of packaging, reduce waste, and ensure better compliance with industry standards. As the market continues to adapt to these innovations, businesses will find themselves better equipped to respond to changing consumer demands and maintain a competitive edge.

Market Demands Driving Innovations in Vertical Packaging Solutions

The vertical packaging machine market is evolving rapidly, driven by various consumer demands and industry trends. According to a recent report by MarketsandMarkets, the global vertical packaging machine market is expected to reach USD 8.86 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.7% from 2020. This surge is primarily attributed to the increasing demand for efficient and adaptable packaging solutions across multiple sectors, including food, pharmaceuticals, and cosmetics.

Innovation in vertical packaging solutions is largely influenced by consumer preferences for convenience and sustainability. As more consumers seek eco-friendly packaging options, manufacturers are investing in technologies that reduce material usage and enhance recyclability. A report from Grand View Research indicates that 66% of consumers are willing to pay more for products that come in sustainable packaging, prompting companies to prioritize sustainable practices in their packaging processes. Additionally, advancements in automation technology are transforming vertical packaging systems, enabling faster production rates and improved accuracy, which helps meet the growing demand for customized packaging designs tailored to specific market needs.

Future Challenges and Opportunities in Vertical Packaging Industry

The vertical packaging industry is set to face a myriad of challenges and opportunities as we approach 2025. One significant challenge is the increasing demand for sustainability, driven by consumers seeking eco-friendly packaging options. According to a recent report by Smithers Pira, the sustainable packaging market is expected to reach $500 billion by 2025, prompting manufacturers to innovate and adapt. Companies must invest in developing biodegradable materials and reducing their carbon footprint, aligning with global sustainability goals.

Another challenge lies in the integration of automation and smart technologies within vertical packaging machines. The implementation of Industry 4.0 is revolutionizing the sector, allowing for enhanced efficiency and real-time monitoring. However, this also necessitates a skilled workforce capable of managing and maintaining these advanced systems. A 2023 study from the International Packaging Association noted that companies incorporating automated solutions could see productivity increases of up to 30%, emphasizing the importance of training and development in the industry.

**Tip:** As businesses navigate these trends, investing in employee training programs focused on new technologies can foster a more competent workforce ready to tackle the evolving demands of vertical packaging.

**Tip:** Additionally, consider exploring partnerships with suppliers of sustainable materials to stay ahead in the competitive landscape and meet consumer expectations for environmentally responsible packaging.

2025 Vertical Packaging Machine Trends

Related Posts

-

Top Strategies for Choosing the Best Bag Filling Machine for Your Business

-

Innovative Solutions for Food Packaging Machine Efficiency and Quality

-

Maximizing Efficiency with Advanced Wrapping Machine Solutions

-

Top Strategies for Choosing the Best Food Packing Machine for Your Business

-

How to Choose the Right Horizontal Wrapping Machine for Your Business Needs

-

Emerging Trends in Food Packaging Technology 2025 Your Ultimate Guide to the Best Food Packing Machines