What is the Best Flow Wrapper Packaging Machine for 2026?

In the fast-evolving world of packaging, businesses are consistently seeking the best solutions. The demand for efficient flow wrapper packaging machines is at an all-time high. These machines are vital for various industries, including food and personal care. They streamline the packaging process, ensuring products remain fresh and presentable.

Choosing the right flow wrapper packaging machine can be daunting. Many options are available, each with unique features. Some prioritize speed, while others focus on versatility. Companies must assess their specific needs to find the best fit. Often, they face challenges: budget constraints and evolving packaging standards can complicate decisions.

The best machine for 2026 will not only enhance efficiency but also support sustainability. With growing environmental concerns, many seek eco-friendly designs. However, balancing technology, cost, and responsibility is a critical, ongoing challenge. Businesses must constantly reflect on their choices to stay competitive in a crowded market.

Overview of Flow Wrapper Packaging Machines

Flow wrapper packaging machines are essential in various industries. They provide efficiency and flexibility in packaging products. These machines can wrap a diverse range of items, from snacks to cosmetics, ensuring they remain fresh and appealing. Their design allows for quick adjustments, catering to different product sizes.

When choosing a flow wrapper, consider the automation level. Fully automated machines enhance speed but may require more maintenance. Semi-automated machines offer a balance between speed and control but may slow down production. **Tip:** Assess your production needs carefully to choose the right type.

Another essential factor is the film type. Films come in various materials, each offering distinct benefits. Some provide better sealed durability, while others enhance visual appeal. **Tip:** Test various film types to find the best fit for your product.

Despite their advantages, flow wrappers can sometimes create complications. Clogging or misalignment may occur, affecting output quality. Regular maintenance is crucial to avoid these issues. Remaining attentive to the machine's functionality helps maintain efficiency.

Overview of Flow Wrapper Packaging Machines - 2026

Key Features to Consider in 2026 Flow Wrap Technology

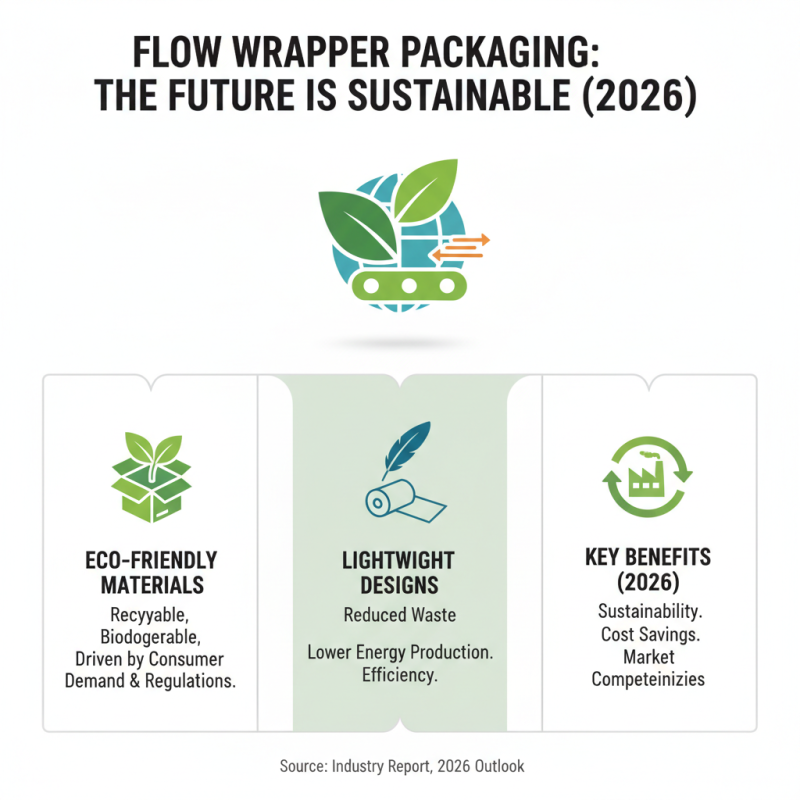

In 2026, the landscape of flow wrapper packaging machines is evolving. The focus is on efficiency and sustainability. A recent industry report shows that 75% of packaging manufacturers prioritize eco-friendly materials. This shift is crucial as consumers demand greener options. Many companies are seeking machines that reduce plastic waste while maintaining durability.

Key features in flow wrap technology include speed and adaptability. The latest models can achieve up to 200 packages per minute. This speed helps manufacturers meet increasing demand. Machine flexibility is also crucial. Adjustable settings allow for different product sizes. Some manufacturers report a 25% increase in production efficiency with versatile machines.

Moreover, automation is becoming a standard expectation. A study indicates that automated packaging solutions can cut labor costs by 30%. However, it’s essential to consider the initial investment and maintenance costs. While high-tech machines offer benefits, not every company is ready for the change. Balancing upfront costs with long-term gains is a challenge many face. This continuing evolution highlights the need for informed decision-making in flow packaging technology.

Top Brands and Models for Flow Wrapper Machines in 2026

As we approach 2026, the demand for efficient and reliable flow wrapper machines continues to rise. Recent industry reports indicate that the global packaging machinery market is expected to grow at a CAGR of 4.3% through 2026. This growth reflects advancements in technology and an increased focus on sustainable packaging solutions. Companies are looking for flow wrappers that can handle various products, from snacks to medical supplies.

Models with enhanced automation features are gaining traction. Automation minimizes human error and increases throughput. Studies show that automated flow wrappers can improve efficiency by up to 30%. Additionally, energy-efficient machines are becoming more crucial. Implementing energy-saving technologies can reduce operational costs significantly, appealing to both manufacturers and environmentally conscious consumers.

**Tip:** Regular maintenance is essential. Even the best machines can falter without proper care. Schedule routine checks to prolong machine life. **Tip:** Consider software integration. Modern flow wrappers now offer connectivity options for real-time monitoring and data analysis. This feature aids in identifying inefficiencies promptly. The need for upgrades and the latest technology will challenge operators to stay current and competitive.

What is the Best Flow Wrapper Packaging Machine for 2026? - Top Brands and Models for Flow Wrapper Machines in 2026

| Model | Speed (Packages/min) | Bag Size (mm) | Power Consumption (kW) | Key Features |

|---|---|---|---|---|

| Model A | 120 | 150x100 | 2.5 | User-friendly, Compact design, High-speed operation |

| Model B | 150 | 200x150 | 3.0 | Versatile, Adjustable settings, Energy-efficient |

| Model C | 100 | 250x200 | 2.0 | Robust construction, Easy maintenance, High throughput |

| Model D | 130 | 180x120 | 2.8 | Smart technology, Low noise, High reliability |

| Model E | 115 | 160x140 | 2.2 | Flexible operation, Quick changeover, Safety features |

Cost Analysis and Budgeting for Flow Wrapper Packaging Solutions

When evaluating flow wrapper packaging solutions for 2026, cost analysis is crucial. A comprehensive budget should include initial costs, maintenance, and operational costs. Reports show that packaging machinery can account for up to 25% of total production costs. Understanding these numbers allows companies to make informed decisions.

Tips: Calculate total cost of ownership. This method provides a clearer picture. Include factors such as energy consumption and labor costs in your assessment. This can reveal unexpected expenses.

Technology advancements are also impacting costs. Automation features can reduce labor needs but require higher initial investments. Industry reports predict that automated systems will decrease operational costs by 15% over five years. Consider the long-term ROI when analyzing your budget.

Tips: Monitor market trends. Keeping an eye on fluctuations in raw material and energy prices can guide your financial planning. Small adjustments in packaging choices can lead to significant savings over time.

Future Trends in Flow Wrapper Packaging Machines and Sustainability

As we approach 2026, the landscape of flow wrapper packaging machines is evolving. Sustainability is no longer a trend; it's essential. More manufacturers are opting for eco-friendly materials. This shift is driven by both consumer demand and regulatory pressures. Lightweight materials are becoming a focal point. They reduce waste and energy in production.

The role of automation in packaging is expanding. Machines are now smarter and more efficient. They can adapt to various packaging sizes and types. However, these advancements raise questions. Are we sacrificing simplicity for technology? Some operators find complex systems challenging. Training staff can be a hurdle. There's a need for user-friendly interfaces.

Furthermore, the industry is grappling with the challenge of recyclability. New materials promise sustainability but may complicate recycling processes. It's crucial to balance innovation with practical environmental impacts. Companies must consider the full lifecycle of their packaging solutions. Are they truly sustainable, or just marketed as such? The journey to sustainable packaging is ongoing and requires continuous evaluation.

Related Posts

-

Revolutionizing the Food Industry with Advanced Flow Wrapper Packaging Machines

-

Discover World Class Manufacturing with the Best Flow Wrap Machine from China

-

How to Choose the Best Wrapping Machine by Understanding Key Technical Specifications and Features

-

Exploring Cost Effective Alternatives to the Best Vertical Packaging Machine for Your Business

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines