How to Choose the Best Flow Wrap Machine for Your Packaging Needs in 2025

In the rapidly evolving landscape of packaging technology, selecting the right equipment is crucial for optimizing efficiency and meeting consumer demands. As we approach 2025, the focus on sustainability and innovation in packaging solutions continues to intensify. Experts in the industry, such as Dr. Samuel Carter, a leading packaging technology specialist, emphasize the importance of making informed decisions regarding machinery. He once stated, "Investing in the right flow wrap machine can significantly enhance your production capabilities while reducing waste."

Choosing the best flow wrap machine involves understanding the specific requirements of your packaging needs. Factors such as the types of products being packaged, the expected output, and the environmental considerations are vital in this decision-making process. With advancements in technology leading to more automated and eco-friendly options, businesses must stay ahead of the curve to ensure they are equipped to handle future demands effectively.

As we delve into the details of how to choose the best flow wrap machine, we will explore essential criteria such as speed, versatility, and cost-effectiveness, equipping you with the knowledge needed to make a strategic investment for your packaging operations in the upcoming year.

Understanding Different Types of Flow Wrap Machines Available in 2025

When selecting a flow wrap machine for packaging needs in 2025, it's essential to understand the various types available in the market. Flow wrap machines can broadly be categorized into horizontal flow wrap machines and vertical flow wrap machines.

Horizontal machines are primarily used for packing a wide range of products, such as snacks and baked goods, while vertical machines are ideal for packaging bulk items like granola bars and pouches. According to a recent industry report by Smithers Pira, the global demand for flow wrap machines is projected to grow at a CAGR of 5.3% through 2025, illustrating the increasing need for efficient packaging solutions across multiple industries.

In addition to the basic categorization, flow wrap machines also differ in their technological specifications. Advanced models now incorporate features like servo-driven technology for improved precision and speed, with some achieving packaging speeds of up to 300 packs per minute.

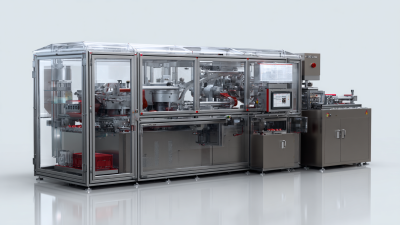

Furthermore, the rise of automation in manufacturing is prompting the adoption of fully integrated flow wrapping systems that can seamlessly connect with upstream and downstream processes, enhancing overall productivity. The International Packaging Association notes that as businesses strive for sustainability, eco-friendly materials are increasingly used in flow wrapping, prompting manufacturers to offer machines compatible with biodegradable films, thus addressing both performance and environmental concerns efficiently.

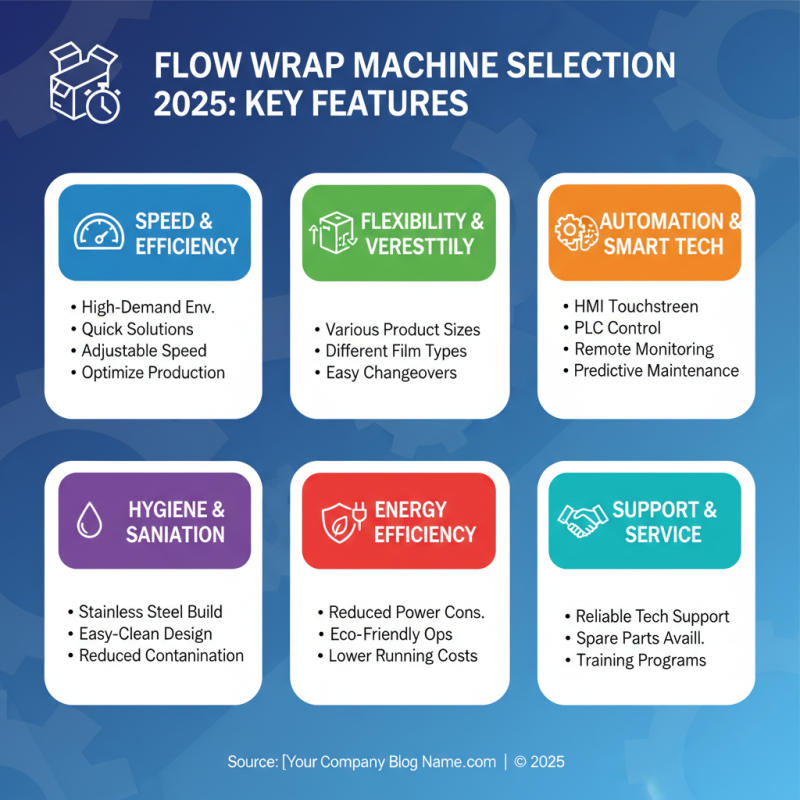

Key Features to Consider When Selecting a Flow Wrap Machine

When selecting a flow wrap machine for your packaging needs in 2025, there are several key features that should be at the forefront of your decision-making process. One critical aspect is the machine's speed and efficiency. This is particularly important in high-demand environments where quick packaging solutions are necessary to keep up with production timelines. A machine that offers adjustable speeds can enhance flexibility, allowing you to optimize performance based on batch sizes and product types.

Another important consideration is the adaptability of the flow wrap machine to various product shapes and sizes. A versatile machine should accommodate a range of items, from small snacks to larger consumer goods, without requiring extensive reconfiguration. Additionally, look for machines that feature user-friendly control systems and programmable settings, which can facilitate ease of operation and minimize downtime. This capability not only enhances efficiency but also contributes to consistent packaging quality, an essential factor in maintaining product integrity and appeal.

Assessing Production Capacity and Speed for Your Packaging Requirements

When selecting a flow wrap machine for your packaging needs in 2025, understanding your production capacity and speed requirements is crucial. The right machine should align with your operational goals, whether you are running a small to medium enterprise or a large-scale operation. You need to assess the volume of products you plan to package daily and how quickly you need the process to be completed. This will help you avoid bottlenecks in production and ensure timely delivery to your customers.

Tips for evaluating production capacity include conducting a thorough analysis of your current workload and a forecast of future demands. Determine the number of products you package per minute and identify peak seasons in your business cycle. Additionally, consider the adaptability of the machine; can it handle fluctuations in order sizes and different product types? These factors will guide you in choosing a machine that can grow with your business and fulfill varying packaging demands efficiently.

Speed is another critical element when selecting a flow wrap machine. Machines with higher wrapping speeds can significantly reduce labor costs and increase throughput. However, ensure that the speed of the machine does not compromise the packaging quality. It's important to keep balance in mind – the fastest machine may not always be the best choice if it leads to an increase in defective products. Evaluate the machine’s specifications thoroughly to find the ideal blend of speed and reliability that meets your unique packaging requirements.

Flow Wrap Machine Production Capacity and Speed Comparison (2025)

Evaluating Material Compatibility and Packaging Options

When selecting a flow wrap machine for your packaging needs in 2025, understanding material compatibility is crucial. Different packaging materials, such as films made from polyethylene, polypropylene, or compostable sources, each have unique properties that affect sealing and durability. Ensuring that the flow wrap machine can handle the specific material you choose will enhance efficiency and product preservation. Look for machines that offer versatile settings to accommodate various materials, as this will provide greater flexibility as your packaging requirements evolve over time.

**Tips:** When assessing material compatibility, consider the thickness and stretchability of the film. Thinner films may be suitable for lighter products, while sturdier materials are essential for heavier or fragile items. Additionally, experiment with trial runs to gauge how different materials perform with your chosen machine.

Another key aspect to consider is the type of packaging options your flow wrap machine can support. Depending on your product, you may need to explore options such as vacuum sealing, modified atmosphere packaging, or standard flow wrapping. Each option will help maintain the integrity and freshness of your products, catering to specific market demands.

**Tips:** Always check the machine’s ability to switch between different packaging formats swiftly, as this can significantly improve production efficiency and minimize downtime when adapting to changing product lines.

How to Choose the Best Flow Wrap Machine for Your Packaging Needs in 2025

| Parameter | Description | Compatibility | Speed (Units/Min) | Price Range ($) |

|---|---|---|---|---|

| Machine Type A | High-speed flow wrapper for snacks | Compatible with film and paper | 200 | 15,000 - 20,000 |

| Machine Type B | Versatile flow wrapper for bakery items | Best with plastic films | 150 | 10,000 - 15,000 |

| Machine Type C | Economical flow wrapper for retail products | Works well with paper and biodegradable films | 100 | 5,000 - 8,000 |

| Machine Type D | High-speed wrapper for frozen foods | Effective with multilayer films | 180 | 20,000 - 25,000 |

Budgeting for Purchase, Maintenance, and Upgrades of Flow Wrap Machines

When considering the purchase of a flow wrap machine, proper budgeting is essential to ensure long-term satisfaction and efficiency. Initially, you must account for the purchase price, which can vary widely based on the machine's capabilities and specifications. It's advisable to outline a clear budget that includes not only the cost of the machine itself but also additional expenses such as installation, training for operators, and potential customizations to meet your specific packaging needs.

Maintenance and upgrades are significant aspects of the total cost of ownership that are often overlooked. Regular maintenance should be factored into your budget to prevent unexpected breakdowns, which can lead to costly downtime. Planning for upgrades is also vital, as technology advances can enhance efficiency and output. Consider setting aside a portion of your budget for periodic upgrades to keep your machine competitive and functional over time.

Tips:

- Conduct thorough research to find a machine that meets your requirements without overspending on unnecessary features.

- Create a maintenance schedule with clear timelines and costs, which can help avoid larger repair expenses in the future.

- Always keep an emergency fund for unforeseen repairs, so your operation remains smooth and uninterrupted.

Related Posts

-

Revolutionizing the Food Industry with Advanced Flow Wrapper Packaging Machines

-

Discover World Class Manufacturing with the Best Flow Wrap Machine from China

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine