How to Choose the Right Food Packing Machine for Your Business Needs

In the competitive landscape of the food industry, selecting the right food packing machine is crucial for enhancing productivity and ensuring product integrity. According to recent industry reports, the global food packaging machinery market is projected to reach $47.2 billion by 2026, growing at a CAGR of 4.6% from 2021 to 2026. This growth highlights the increasing demand for efficient and innovative packing solutions that meet stringent safety and sustainability standards. Businesses must assess their specific needs, including production volume and packaging types, to choose a machine that not only optimizes operations but also aligns with the latest technological advancements. With a myriad of options available, understanding the features and capabilities of different food packing machines is essential for making an informed investment that can significantly impact overall business performance.

Factors to Consider When Selecting a Food Packing Machine

When selecting a food packing machine for your business, it is essential to consider several key factors that influence efficiency and productivity. First, assess the type of food products you handle. Different machines are designed for various functions, such as filling, labeling, and packaging. Understanding whether you need a primary packing solution or a more complex system, like a robotic station for automation, can significantly narrow your options. The market is evolving to include advanced technologies that enhance speed and accuracy, making it crucial to choose a machine that aligns with your production goals.

Another important aspect is the scalability of the machine. As your business grows, so will your production needs. Opting for flexible packing solutions allows for easy upgrades or expansions, which is vital in a dynamic market environment. Additionally, consider the ease of operation and maintenance to reduce downtime. Training requirements for your staff and the long-term sustainability of the machine, such as energy efficiency and material usage, should also be factored in. With these considerations, businesses can effectively choose a food packing machine that not only meets their current needs but also supports future growth.

Another important aspect is the scalability of the machine. As your business grows, so will your production needs. Opting for flexible packing solutions allows for easy upgrades or expansions, which is vital in a dynamic market environment. Additionally, consider the ease of operation and maintenance to reduce downtime. Training requirements for your staff and the long-term sustainability of the machine, such as energy efficiency and material usage, should also be factored in. With these considerations, businesses can effectively choose a food packing machine that not only meets their current needs but also supports future growth.

Types of Food Packing Machines: Which One Suits Your Business?

When it comes to selecting the right food packing machine for your business, understanding the various types available is crucial. The food packing machinery market has witnessed substantial growth, estimated to reach $50.92 billion by 2025, according to a report by Grand View Research. This growth is driven largely by the increasing demand for packaged food products and the need for efficient packaging solutions.

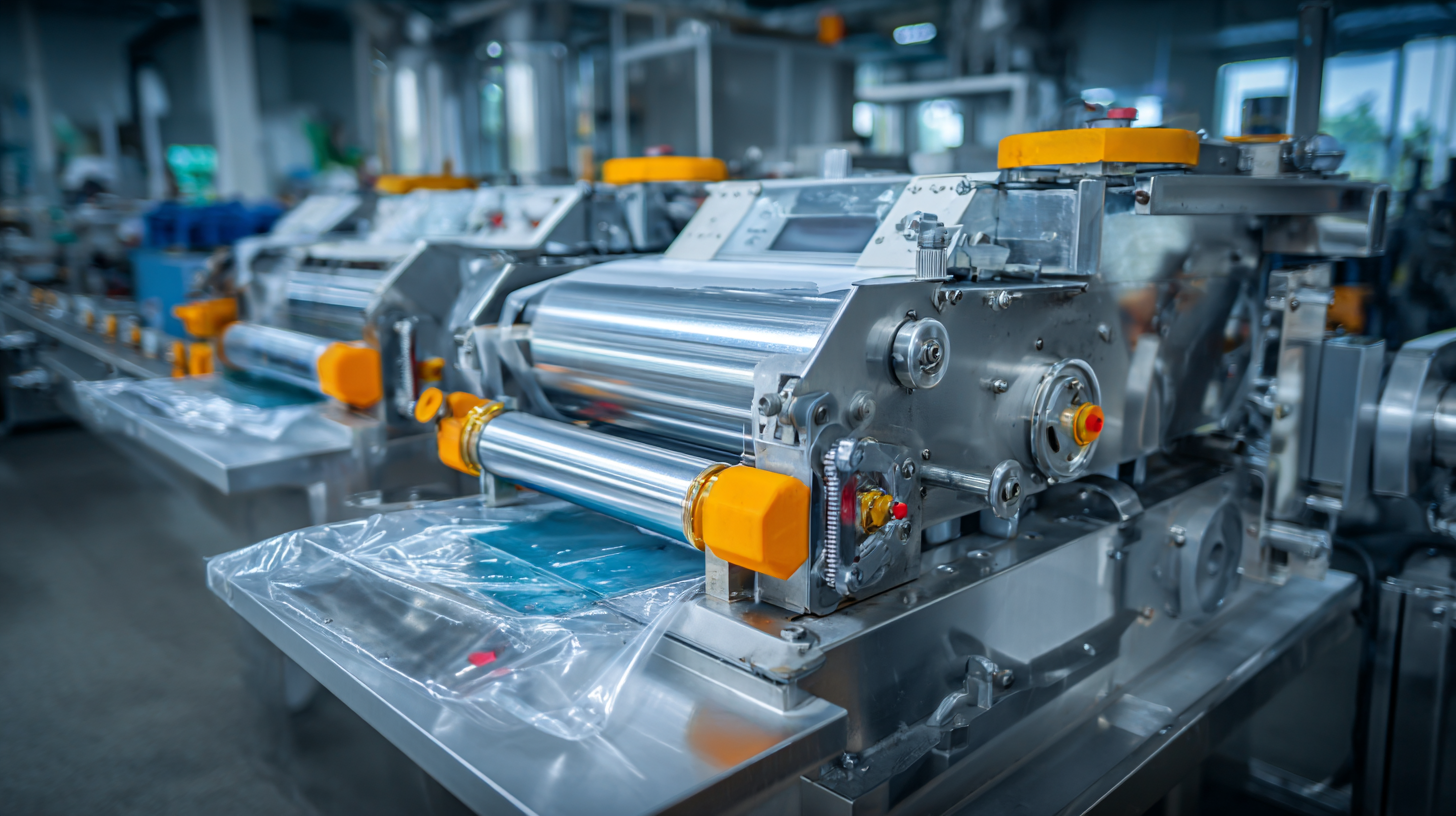

There are several key types of food packing machines that businesses can consider. Flow wrapping machines are ideal for high-speed packing of products such as snacks and bakery items, providing a tight seal that extends shelf life. Conversely, vertical form-fill-seal machines are perfect for bulk items like grains and powders, offering flexibility in packaging various dimensions. In addition, vacuum packing machines help in preserving freshness by removing air from packages, making them suitable for meat and perishable goods. Understanding these options allows businesses to choose a machine that aligns with their production needs and product types, ultimately enhancing operational efficiency and product quality.

How to Choose the Right Food Packing Machine for Your Business Needs - Types of Food Packing Machines

| Machine Type | Best For | Speed (Units/Min) | Cost Range | Key Features |

|---|---|---|---|---|

| Vertical Form Fill Seal | Powder and Granular Products | 20-60 | $15,000 - $50,000 | Compact, Automated, Versatile |

| Horizontal Flow Wrapper | Snacks and Bakery Products | 30-80 | $20,000 - $60,000 | Flexible Packaging, High Speed, Easy to Use |

| Pouch Packaging Machine | Liquid and Solid Products | 10-50 | $25,000 - $70,000 | Customizable, User-Friendly, Multi-Function |

| Cup Filling Machine | Dairy and Sauces | 15-40 | $30,000 - $80,000 | Accurate Filling, High Hygienic Standards, Automated Options |

| Shrink Wrapping Machine | Bottles and Cans | 20-70 | $10,000 - $45,000 | Tight Sealing, Enhanced Product Protection, Quick Setup |

Understanding Your Production Volume and Its Impact on Machine Choice

When selecting a food packing machine, understanding your production volume is crucial. According to a report by Grand View Research, the global food packaging machinery market is expected to reach $50.5 billion by 2025, largely driven by the increasing demand for processed and packaged food. This demand forces businesses to align their production capabilities with efficient packing solutions that can handle their specific output requirements.

For instance, companies with high production volumes, exceeding 500 units per hour, should consider high-speed vertical form-fill-seal (VFFS) machines which can optimize packing efficiency while maintaining product quality. On the other hand, businesses producing smaller volumes might benefit from semi-automatic machines that offer flexibility but are less capital intensive.

Data from PMMI, the Association for Packaging and Processing Technologies, suggests that packaging line downtime can significantly affect overall productivity, emphasizing the importance of choosing a machine that meets your production volume without excess strain on operational resources.

Budgeting for Your Food Packing Machine: Costs to Anticipate

When budgeting for a food packing machine, it’s crucial to understand the various costs involved beyond the initial purchase price. Start by considering the type of machine that best fits your production needs, as prices can vary significantly based on features and automation levels. For instance, semi-automatic machines might be more budget-friendly, while fully automatic systems could require a larger upfront investment but offer long-term efficiency gains.

Additionally, don’t overlook the ongoing costs associated with maintenance, parts replacement, and potential upgrades. The reliability of the machine plays a pivotal role in production efficiency, so investing in a reputable brand with good after-sales service can save costs in the long run. Training for your staff and any necessary modifications to your facility to accommodate the new machinery should also be factored into your budget. By taking a comprehensive view of costs related to a food packing machine, businesses can make informed decisions that align with their financial goals and operational needs.

Budgeting for Your Food Packing Machine: Anticipated Costs

Key Features and Specifications to Look for in Food Packing Machines

When selecting the right food packing machine for your business, it is crucial to consider key features and specifications that align with your production needs. One vital aspect is the machine's speed and efficiency. High-speed packing machines can significantly enhance your production line, reducing bottlenecks while maintaining quality. Assess the output rate per minute, ensuring it meets your demand without compromising the accuracy of packaging.

Another important feature to evaluate is the machine's versatility. Look for food packing machines that can accommodate various packaging styles, such as vacuum sealing, thermal sealing, or flow wrapping. This flexibility allows your business to adapt to changing market trends and product lines without the need for significant additional investment. Additionally, consider the size and footprint of the machine, ensuring it fits within your workspace without disrupting your existing operations. Robust safety features and ease of maintenance are also essential specifications that contribute to smooth and safe production processes.