How to Choose the Right Sealing Machine for Your Packaging Needs

In the fast-evolving world of packaging, selecting the right sealing machine is crucial for maintaining product integrity and ensuring efficiency in operations. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $46 billion by 2024, driven largely by the demand for high-quality sealing solutions. As businesses strive to meet both consumer expectations and regulatory standards, the sealing machine emerges as a key component in the packaging process. With various types available — from heat sealers to vacuum sealers — understanding the specific needs of your product, and the operational requirements of your facility, can significantly impact your overall packaging effectiveness. In this blog, we will explore the essential factors to consider in choosing the right sealing machine tailored to your unique packaging needs, equipping you with the knowledge to make informed decisions in a competitive landscape.

Understanding Different Types of Sealing Machines for Packaging

When selecting a sealing machine for your packaging needs, it's crucial to first understand the different types available on the market. The most common types include impulse sealers, vacuum sealers, and continuous band sealers.

Impulse sealers are widely used for their simplicity and efficiency, making them ideal for small to medium-sized operations. They use a heated element to create a seal, and their compact design allows for easy integration into any workspace.

On the other hand, vacuum sealers are perfect for applications requiring longer shelf life, as they remove air from the packaging, thus preventing oxidation and spoilage. These machines are essential for industries such as food packaging, where preserving freshness is key.

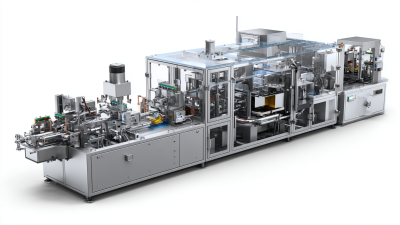

Continuous band sealers provide a reliable solution for high-volume packaging, sealing bags at a consistent rate. Their automation minimizes labor costs and improves efficiency, making them ideal for large-scale production environments. By understanding these types, you can better assess which sealing machine aligns with your specific operational needs and product requirements.

Key Factors to Consider When Selecting a Sealing Machine

When selecting a sealing machine for your packaging needs, it's essential to consider several key factors to ensure optimal performance and efficiency. The demand for packaging solutions is on the rise, with the automated bag packaging machine market projected to grow from $520 million in 2022 to an impressive $810 million by 2030. This growth reflects a CAGR of 6.2% from 2024 to 2030, highlighting the importance of making informed decisions when choosing sealing equipment.

One critical aspect to evaluate is the type of materials your sealing machine will work with. Consider whether you need to seal flexible films, pouches, or rigid containers, as each application requires different sealing technologies. Additionally, the sealing speed and capacity are vital factors, especially as businesses aim to optimize production lines without compromising on quality.

**Tips:** Always check for compatibility with your existing production setup and ensure that the machine can handle the required volume. Furthermore, don't overlook the importance of after-sales support and maintenance to safeguard your investment. By carefully assessing these criteria, you can select a sealing machine that meets your specific packaging requirements while keeping pace with industry trends.

| Factor | Description | Considerations |

|---|---|---|

| Type of Sealing Machine | Choose between impulse, direct heat, or vacuum sealing based on product needs. | Consider the types of materials and packaging methods used. |

| Production Volume | Assess the output requirement to determine the machine speed and capability. | Ensure the machine can handle peak production demands without issues. |

| Ease of Use | Evaluate user interface, controls, and setup requirements. | Look for features like digital controls and automatic adjustments. |

| Maintenance Requirements | Understand the maintenance needed for longevity and efficiency. | Consider ease of accessibility for repairs and part replacements. |

| Cost | Compare prices, taking into account potential return on investment. | Assess budget constraints and available financing options. |

| Size & Footprint | Determine the physical space available for the machine. | Consider layout and workflow when placing the machine. |

Evaluating Production Volume and Speed in Sealing Solutions

When assessing the right sealing machine for your packaging needs, understanding production volume and speed is crucial. Industry reports indicate that packaging machinery can improve production efficiency by up to 30%, particularly with advancements in high-speed sealing technologies. For example, a rotary sealing machine can handle around 150-300 packages per minute, significantly accelerating output compared to traditional methods. Evaluating your production volume requirements—whether low, medium, or high—can guide you in selecting a machine that balances speed with reliability.

Tip: Consider conducting a thorough analysis of your packaging lines to determine peak production times. This will help inform the speed capacity you need from a sealing machine. For instance, if your operation peaks at 2,000 units per day, investing in a machine that can sustain at least 200 units per hour would be beneficial to meet demand without compromising quality.

Additionally, testing the sealing technology’s adaptability to various materials is essential. Reports suggest that consistent seal integrity reduces product spoilage by up to 15%, highlighting the importance of proper sealing solutions that can accommodate different packaging substrates. Always leverage testing and simulations to identify the best combination of speed and production volume for your specific application.

Sealing Machine Performance Comparison

Material Compatibility: Choosing the Right Sealing Technology

When selecting a sealing machine, material compatibility is crucial for ensuring the effectiveness of the packaging. Different sealing technologies, such as thermal, ultrasonic, or impulse sealing, interact uniquely with various materials. For instance, polyethylene and polypropylene require consistent heat sealing, while laminates might need specialized ultrasonic techniques. According to recent industry reports, nearly 30% of food safety issues stem from inadequate sealing practices, highlighting the significance of choosing the right sealing technology aligned with your packaging material.

When selecting a sealing machine, material compatibility is crucial for ensuring the effectiveness of the packaging. Different sealing technologies, such as thermal, ultrasonic, or impulse sealing, interact uniquely with various materials. For instance, polyethylene and polypropylene require consistent heat sealing, while laminates might need specialized ultrasonic techniques. According to recent industry reports, nearly 30% of food safety issues stem from inadequate sealing practices, highlighting the significance of choosing the right sealing technology aligned with your packaging material.

Tips: Always conduct preliminary testing with your chosen sealing technique to guarantee that the package remains airtight under expected storage conditions. Additionally, consider the shelf life requirements of your products; packaging that maintains both food safety and longevity often utilizes multilayer materials that work best with specific sealing methods.

Another key consideration is chemical compatibility. Some packaging materials may react adversely with the contents, compromising safety and efficacy. Selecting materials and sealing technologies that ensure stability will prevent contamination, particularly in biologic formulations. Recent findings indicate that ensuring compatibility in these applications can improve shelf life by up to 50%, making informed selections even more critical for manufacturers.

Budgeting for Your Sealing Machine: Costs and Maintenance Considerations

When selecting a sealing machine, budgeting plays a crucial role in ensuring that your investment aligns with your packaging needs. According to a recent industry report by Smithers, the global packaging machinery market is projected to reach $48 billion by 2026. Within this market, sealing machinery accounts for a significant share, driven by the growing demand for efficient, automated packaging solutions. Therefore, understanding the initial costs and ongoing maintenance expenses is essential for making an informed purchase.

The initial cost of sealing machines can vary widely, ranging from a few hundred to tens of thousands of dollars, depending on the machine's capabilities and automation level. Beyond the purchase price, maintenance costs are an important consideration. The Packaging Machinery Manufacturers Institute (PMMI) indicates that routine maintenance can account for up to 10% of the total operational costs of packaging machinery annually.

Investing in a reliable sealing machine with efficient maintenance protocols not only reduces downtime but can also extend the machine's lifespan and ensure consistent packaging quality. Thus, thorough budgeting should incorporate both upfront costs and projected maintenance to optimize the overall value of your sealing equipment.

Related Posts

-

How to Choose the Best Wrapping Machine by Understanding Key Technical Specifications and Features

-

7 Top Benefits of the Best Form Fill Seal Machine for Global Buyers

-

Exploring the Unique Features and Applications of the Best Form Fill Seal Machines: A Complete Guide

-

Flow Wrap Machines: An In-Depth Comparison of Features, Costs, and Performance

-

Top Strategies for Sourcing the Best Food Packing Machine Globally

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs