How to Choose the Best Tray Sealing Machine for Your Business?

In the fast-paced food packaging industry, choosing the right tray sealing machine is crucial. The global market for tray sealing machines is projected to reach $3.6 billion by 2027, according to industry reports. This growth highlights the increasing demand for efficient and reliable packaging solutions. A suitable machine can enhance operational efficiency and reduce production costs.

However, not all tray sealing machines are created equal. Factors such as size, sealing speed, and material compatibility significantly impact your decision. Often, businesses overlook these details, leading to challenges in production. For instance, a machine that cannot handle specific tray materials can create bottlenecks and additional expenses. It's essential to assess your business’s specific needs carefully.

Investing in a tray sealing machine is not just about the initial cost. Long-term performance and maintenance should also be considered. Many companies find themselves grappling with machines that require frequent repairs or are inefficient. Thus, evaluating not only the machine's capabilities but also customer support and warranty options is vital for sustainable success in a competitive market.

Understanding the Different Types of Tray Sealing Machines

When selecting a tray sealing machine, it's crucial to understand the various types available in the market. The two primary types are manual and automatic machines. Manual machines require human operation and are ideal for small-scale businesses. They are budget-friendly but can be slower and inconsistent. Automatic machines, on the other hand, handle larger volumes with much greater efficiency. According to industry reports, automatic sealing machines can boost packaging speed by up to 50%. Yet, they come with a higher initial investment.

Tip: Consider your production volume before making a choice. If you are just starting, a manual machine may suffice. However, for growing businesses, investing in an automatic machine can save costs in the long run.

Another important type is the vacuum tray sealing machine. This type removes air from packaging to extend shelf life. Studies show that vacuum sealed products can last 3 to 5 times longer than traditionally sealed items. However, vacuum machines can be more complex and potentially require additional training for staff.

Tip: Evaluate your product's shelf life and desired freshness before deciding on a machine. It’s essential to balance quality and cost-effectiveness. Analyze whether the added benefits match your business's specific needs, as some features may not be necessary for all products.

Comparison of Different Types of Tray Sealing Machines

Evaluating Your Business Needs for Tray Sealing Solutions

When evaluating your business needs for tray sealing solutions, start by identifying your production volume. Think about the number of trays you seal daily. If your volume is high, an automatic or semi-automatic machine may suit you. For small operations, a manual model might provide the flexibility needed without the upfront costs.

Consider the types of products you will seal. Food items, medical supplies, or other goods may require different sealing technologies. Reflect on whether your products need specific temperature controls or gas flush capabilities. Look at the shelf life requirements too. It’s essential to align your machine's capabilities with your product needs to avoid spoilage or waste.

Budget is a key factor. Equipment can be expensive, but cheap options may lead to frequent breakdowns. This could cause delays and dissatisfaction. Think critically about long-term costs, including maintenance and repairs. Understand that investing in quality now might save you headaches later.

How to Choose the Best Tray Sealing Machine for Your Business? - Evaluating Your Business Needs for Tray Sealing Solutions

| Feature | Importance Level | Considerations | Estimated Budget ($) |

|---|---|---|---|

| Machine Speed | High | Consider your production volume | 5,000 - 15,000 |

| Type of Sealing | Medium | Choose between vacuum, MAP, or simple sealing | 3,000 - 10,000 |

| Size of Trays | High | Ensure compatibility with your product packaging | 2,000 - 7,000 |

| Ease of Use | Medium | Training needs and operational simplicity | 1,000 - 5,000 |

| Durability and Maintenance | High | Look for robust construction and service support | 4,000 - 12,000 |

| Energy Efficiency | Medium | Consider operational costs over time | 2,000 - 8,000 |

Key Features to Consider When Choosing a Tray Sealing Machine

Choosing the right tray sealing machine involves weighing several key features. One important aspect is the machine’s sealing capacity. Understand your production needs. A machine that seals 20 trays per minute may not suffice if your demand is higher. Efficiency matters.

Next, consider the material compatibility. Different machines handle various tray materials. Your choice should align with your product’s packaging needs. Test a few machines to see which ones perform best with your materials. You might find that some handle plastics better, while others are more efficient with compostables.

Finally, focus on ease of use. A user-friendly interface can minimize training time and reduce errors. Look for machines that offer intuitive controls. Reflect on your team’s skills; a complex machine may create frustration during busy hours. Evaluate all these features to find the machine that fits best.

Comparing Cost-Effectiveness of Various Tray Sealing Machines

When selecting a tray sealing machine, cost-effectiveness is crucial. A recent industry report highlighted that companies can save up to 20% by choosing the right machine based on production needs. The initial purchase cost is essential, but ongoing expenses matter more in the long run. Look at energy consumption, maintenance, and material costs for a comprehensive view.

Consider automation levels and production speed. Manual machines might be cheaper upfront but often lead to higher labor costs. An automatic or semi-automatic machine may demand a larger investment, yet it pays off with increased efficiency and lower labor costs. A report by Packaging Machinery Manufacturers Institute noted that automation can reduce production time by about 30%.

Tips: Always assess machine specifications carefully. Check the warranty terms and customer service quality. Numbers don’t tell the whole story; sometimes, lower-priced machines come with hidden costs. Evaluate the machine’s compatibility with your packaging materials. It’s a common mistake to overlook this aspect. An incompatible machine can drive costs up significantly due to material waste and unplanned downtime. Invest in a machine that fits your unique needs, as this decision can make or break your profit margin.

Assessing Manufacturer Reliability and Support Services

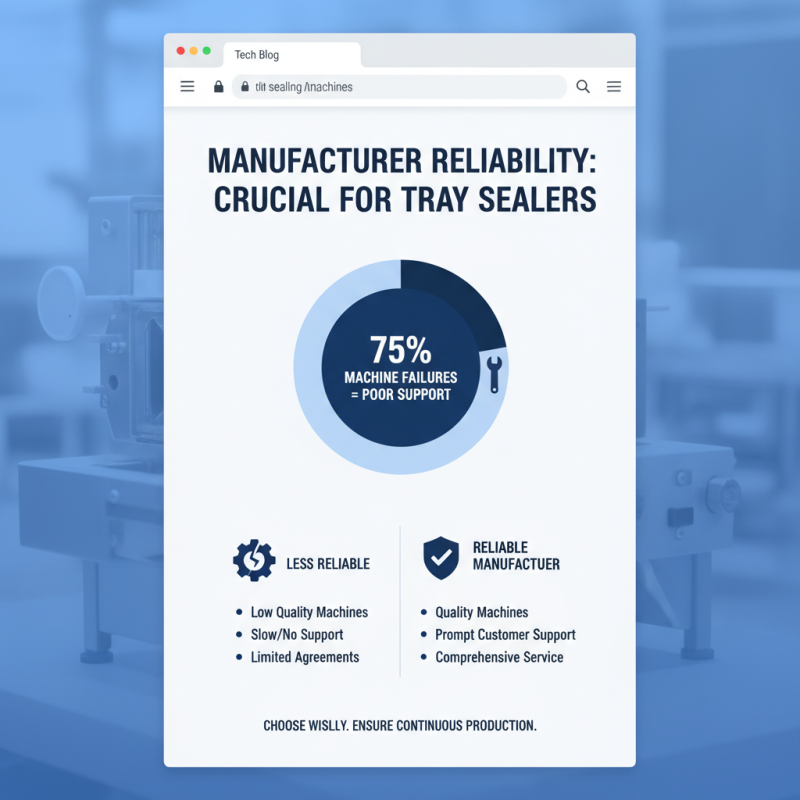

When selecting a tray sealing machine, manufacturer reliability is crucial. A recent industry report highlights that 75% of machine failures stem from poor support services. This statistic underscores the importance of evaluating a manufacturer's reputation. Reliable manufacturers provide not just quality machines, but also prompt customer support and comprehensive service agreements.

Assessing support services can be complex. Check for availability of technical assistance. According to research, 65% of businesses experience delays due to insufficient support. Delays can impact production schedules and lead to lost revenue. Look for manufacturers that offer extensive warranties and training programs. Training can minimize operation errors and maximize efficiency.

Personal experience reveals challenges in maintenance. Some manufacturers provide limited parts availability, complicating repairs. Reflect on feedback from other users. Are they satisfied with service response times? This insight can reveal potential shortcomings. Balancing cost with reliability and support is key to a successful investment. Investing in a reliable manufacturer can significantly reduce long-term operational headaches.

Related Posts

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Discover Excellence in Manufacturing with the Leading Horizontal Packaging Machine from Top Chinese Factory

-

Top 5 Global Certifications You Need for the Best Pouch Machine in 2023

-

Flow Wrap Machines: An In-Depth Comparison of Features, Costs, and Performance

-

Revolutionizing the Food Industry with Advanced Flow Wrapper Packaging Machines

-

Leading the World with Chinas Best Bag Filling Machine Innovation