The Ultimate Guide to Choosing the Right Sealing Machine for Your Packaging Needs

When it comes to packaging, the right choice of sealing machine can significantly impact product integrity and shelf life. As industry expert John Smith, a leading engineer at PackTech Solutions, aptly states, "The sealing machine you choose should not only meet your current needs but also adapt to future innovations in packaging." With the rapid advancements in packaging technology, selecting a sealing machine that aligns with your specific requirements can seem overwhelming.

This guide aims to simplify the decision-making process by providing essential tips tailored to various packaging needs. From understanding different sealing technologies to evaluating machine specifications, our goal is to equip you with the knowledge necessary to make an informed choice. Whether you are a small business owner looking to scale your operations or a large manufacturer seeking efficiency, the right sealing machine can elevate your packaging process, ensuring product quality and customer satisfaction.

Understanding Different Types of Sealing Machines for Packaging

When it comes to packaging, choosing the right sealing machine is crucial. The market offers a variety of sealing machines, each tailored for different packaging needs. Understanding the types available can significantly impact your production efficiency and product protection. According to a recent report by MarketsandMarkets, the global packaging machinery market is projected to reach $56 billion by 2025, indicating the growing emphasis on efficient packaging solutions, including sealing technologies.

Among the major types of sealing machines are heat sealers, vacuum sealers, and pressure sealers. Heat sealers utilize heat to correct the packaging materials' bonding, ideal for plastics and films. They account for approximately 30% of the packaging machinery market, primarily due to their versatility in various industries, from food and beverage to medical packaging. Vacuum sealers, on the other hand, remove air from packaging to enhance shelf life, with a market growth rate of around 5% annually, driven by the rising demand for longer-lasting food products. Meanwhile, pressure sealers, often used for paper products, provide a quick and efficient sealing method, especially in mailing and distribution services. Understanding these diverse sealing machines helps businesses make informed decisions tailored to their specific requirements.

Key Factors to Consider When Choosing a Sealing Machine

When selecting the right sealing machine for your packaging needs, several key factors should be taken into account to ensure optimal performance and sustainability. Firstly, consider the type of products being packaged. Different items require specific sealing methods; for instance, delicate food items may need heat sealing to preserve freshness while preventing contamination, whereas heavy-duty industrial products might benefit from vacuum sealing to extend shelf life and protect against external elements.

Additionally, the efficiency and environmental impact of the sealing machine are crucial. In light of recent advancements in sealing technology, particularly maze sealing techniques, newer models are designed to improve energy efficiency, thereby facilitating a transition towards greener industrial practices. These innovations not only enhance operational efficiency but also contribute to significant energy savings and reduced emissions, aligning with the global shift towards a low-carbon economy. Thus, evaluating the environmental credentials of a sealing machine can be as important as its operational capabilities, making it a vital consideration in your purchasing decision.

The Ultimate Guide to Choosing the Right Sealing Machine for Your Packaging Needs

| Feature | Description | Importance Rating (1-5) |

|---|---|---|

| Sealing Type | Indicates the method used for sealing (e.g., heat seal, vacuum seal, impulse seal). | 5 |

| Production Speed | Speed of the sealing machine, measured in packages per minute. | 4 |

| Machine Size | Dimensions of the machine; important for space allocation. | 3 |

| Material Compatibility | The types of materials the machine can seal (e.g., plastic, foil, paper). | 5 |

| Ease of Use | How user-friendly the machine is, including training and setup. | 4 |

| Maintenance Requirements | Frequency and type of maintenance required to keep the machine running. | 3 |

| Cost | Total price of the machine and its operating costs. | 4 |

| Warranty and Support | Length and coverage of warranty, along with availability of customer support. | 5 |

Comparing Automatic vs. Manual Sealing Machines

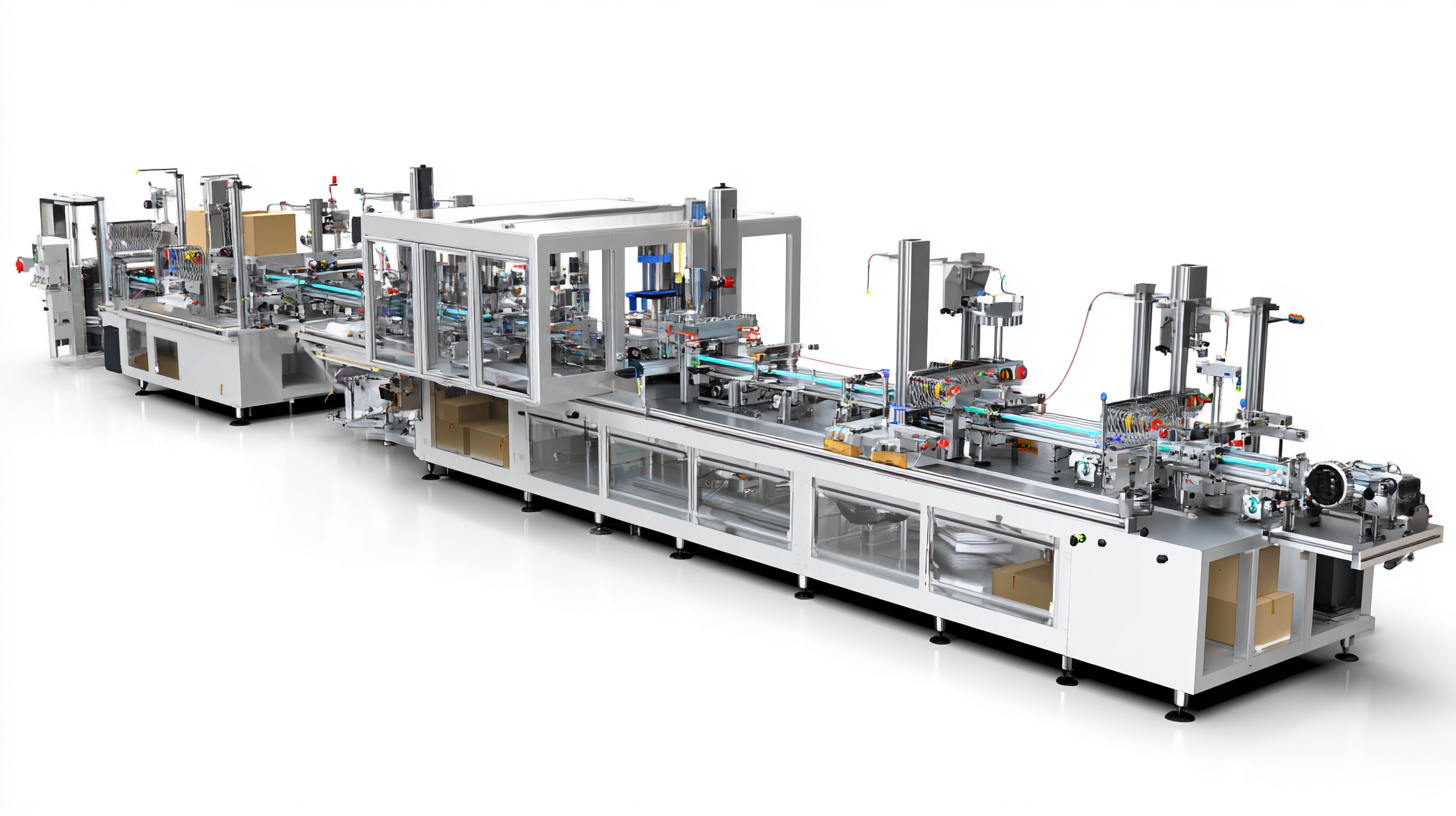

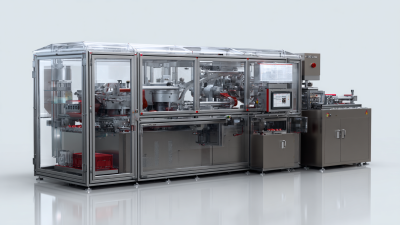

When selecting a sealing machine for packaging, understanding the differences between automatic and manual sealing machines is crucial. Automatic sealing machines are designed for high-volume production, offering speed and efficiency. They can operate continuously with minimal operator intervention, making them ideal for businesses looking to streamline their packaging operations. Additionally, automatic machines often come with advanced features such as adjustable sealing temperatures and integration with conveyor systems, enabling a seamless workflow.

In contrast, manual sealing machines are typically more affordable and require direct operator involvement, making them suitable for smaller businesses or low-volume operations. These machines provide flexibility, allowing operators to pause and adjust the sealing process as needed. However, the trade-off is a slower production rate compared to their automatic counterparts. For companies prioritizing cost-effectiveness and hands-on control, manual machines can be a viable option, especially when the packaging requirements are varied or not standardized. Ultimately, the choice between automatic and manual sealing machines should consider factors such as production volume, budget, and desired operational efficiency.

Evaluating Seal Quality and Production Efficiency

When selecting a sealing machine for packaging, evaluating seal quality is paramount. A well-executed seal not only ensures product freshness and safety but also enhances the overall visual appeal of the package. Testing methods such as peel tests and vacuum decay assessments can provide insights into the integrity of the seals produced by different machines. Factors like temperature, pressure, and dwell time play crucial roles in achieving optimal seal quality, and prospective buyers should carefully analyze these specifications to align with their product requirements.

Production efficiency is another critical consideration in the choice of a sealing machine. Machines that offer higher speeds can significantly reduce overall packaging time, increasing throughput and decreasing labor costs. It's essential to evaluate the machine's capabilities in terms of adaptability and ease of changeover for different packaging formats. By investing in a sealing machine that balances both high seal quality and production efficiency, businesses can maintain a competitive edge in their packaging operations while ensuring customer satisfaction through reliable and appealing products.

Budgeting for Your Sealing Machine Investment

When budgeting for your sealing machine investment, it’s essential to consider not only the initial cost but also the long-term value it can provide. Start by evaluating your specific packaging needs, as this will help determine the type of sealing machine that fits your requirements. Machines vary in price based on features, capacity, and technology, so aligning your budget with your operational demands is crucial.

**Tips:** Compare different models and their costs carefully. Look for machines that offer versatility, allowing you to handle various packaging formats without needing multiple machines. Additionally, factor in maintenance costs and the availability of replacement parts, as these will impact your overall budget.

Beyond the purchase price, consider the potential savings that an efficient sealing machine can bring. Investing in a quality machine may reduce waste and increase productivity, ultimately leading to better profit margins.

**Tips:** Calculate the return on investment (ROI) by estimating how much time and materials you’ll save over the machine's lifespan. This insight can help justify a higher initial cost if the long-term benefits outweigh the expense.

Related Posts

-

How to Choose the Right Sealing Machine for Your Packaging Needs

-

Top 5 Global Certifications You Need for the Best Pouch Machine in 2023

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

Emerging Trends in Food Packaging Technology 2025 Your Ultimate Guide to the Best Food Packing Machines

-

7 Compelling Reasons Why Investing in a Pouch Filling Machine Can Boost Your Production Efficiency by 30%

-

Maximizing Efficiency with Advanced Wrapping Machine Solutions