7 Compelling Reasons Your Business Needs an Automatic Packaging Machine Today

In today's rapidly evolving marketplace, the efficiency and effectiveness of packaging processes can make or break a business's success. According to a recent report by the Freedonia Group, the demand for packaging machinery is projected to grow at an annual rate of 4.2% through 2025, emphasizing the increasing importance of automation in the packing sector. An automatic packaging machine not only streamlines production but also enhances product safety and presentation. With consumer preferences shifting toward sustainability and convenience, businesses that invest in these advanced machines can significantly reduce labor costs and increase throughput. This article will explore seven compelling reasons why integrating an automatic packaging machine into your operations is no longer just an option, but a necessity for staying competitive in today's dynamic business environment.

Understanding the Importance of Automation in Packaging Processes

In today's competitive market, automation in packaging processes is not just a trend; it is a necessity for businesses aiming for efficiency and growth. The integration of advanced technologies like machine learning and computer vision into packaging systems significantly enhances accuracy and speed. By minimizing human error and optimizing workflows, automated packaging machines can lead to increased throughput and reduced operational costs.

Tips for successful automation implementation include investing in employee training programs to ensure staff is comfortable with new technologies. A gradual transition with pilot projects can help identify potential challenges before full-scale implementation. Additionally, regularly assessing technology investments will keep your packaging processes aligned with industry advancements and market demands.

Understanding the importance of automation also involves staying updated on market analyses, as reports indicate a notable correlation between tech investments and growth in the packaging machinery sector. Companies that prioritize automation will not only streamline their processes but will also position themselves favorably in the evolving landscape of the packaging industry.

Key Benefits of Implementing an Automatic Packaging Machine for Efficiency

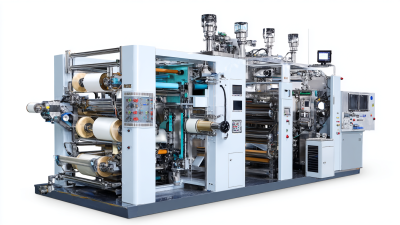

In today’s fast-paced market, implementing an automatic packaging machine offers a multitude of benefits that can significantly enhance business efficiency. By automating packaging processes, companies can reduce labor costs and minimize human error, ultimately leading to increased productivity. The integration of IoT and smart packaging technologies is also becoming vital. These innovations allow for better tracking and management of packaging operations, ensuring a seamless workflow that caters to the growing consumer demand for eco-friendly and recyclable options.

Tip: When selecting an automatic packaging machine, consider its compatibility with your product line. Machines that can adapt to different types of products can save time and money as your business grows.

Moreover, the demand for high-performance machinery is on the rise, especially as industries shift towards more sustainable practices. Businesses that invest in the latest packaging technology can not only meet consumer expectations but also stay ahead of regulatory trends focusing on environmental impact. Companies that are proactive in this area will not only enhance their operational efficiency but also improve their market competitiveness.

Tip: Regular maintenance of your automatic packaging machine is crucial. Establish a routine check-up schedule to ensure optimal performance and longevity of the equipment.

How Automatic Packaging Machines Enhance Product Consistency and Quality

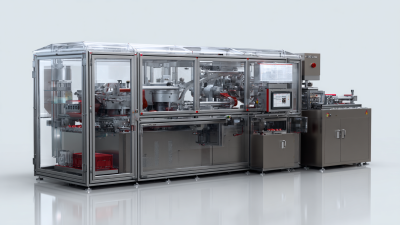

In the competitive landscape of today's market, product consistency and quality can make or break a business. Automatic packaging machines play a vital role in enhancing these aspects, ensuring that every item leaving the production line meets rigorous standards. By automating the packaging process, businesses can reduce human error, which is often the culprit behind inconsistencies. Each package is filled, sealed, and labeled uniformly, which not only boosts productivity but also cultivates trust with consumers who expect a certain level of quality.

Moreover, automatic packaging machines are designed to adapt to various product sizes and types without sacrificing precision. This flexibility allows businesses to maintain their brand standards even as product lines evolve. With advanced technology, these machines can monitor each phase of the packaging process, making real-time adjustments to maintain quality control. Consequently, companies can enhance their reputation for reliability, ensuring that customers receive products that consistently meet their expectations, while also streamlining their operations for increased efficiency.

The Cost-Effectiveness of Investing in Automatic Packaging Solutions

Investing in automatic packaging solutions can significantly enhance your business's cost-effectiveness. With rising labor costs and increasing demands for efficiency, an automatic packaging machine can streamline operations, reducing the need for manual labor. This not only cuts down on wages but also minimizes human error, leading to consistently high-quality packaging, which is crucial for customer satisfaction.

Tip: When selecting an automatic packaging machine, consider the volume and variety of products you handle. A versatile machine can adapt to different packaging styles without requiring extensive modifications, saving both time and money. Additionally, look for machines that offer easy maintenance, as this can further reduce downtime and repair costs.

Another key factor in the cost-effectiveness of automatic packaging is the reduction in material waste. Automatic machines are typically designed to optimize the use of packing materials, ensuring that less is wasted in the process. This can significantly lower your packaging expenditures over time.

Tip: Regularly analyze your packaging material usage and consider switching to eco-friendly options that may also lower costs in bulk purchasing. Sustainable choices can not only positively impact your bottom line but also enhance your brand image in an increasingly eco-conscious market.

Future-Proofing Your Business with Advanced Packaging Technology

In today’s fast-paced market, the need for efficiency and precision in packaging has never been more critical. Embracing advanced packaging technology not only streamlines operations but also ensures that businesses can adapt to the evolving demands of consumers.

Future-proofing your business with automatic packaging systems means investing in equipment that can grow with your company. These machines are designed to accommodate various products and packaging styles, making them versatile and cost-effective in the long run. As consumer preferences continue to change, businesses equipped with advanced technology are better positioned to pivot swiftly, allowing for a more agile response to market trends. Furthermore, the integration of smart technology into these machines provides valuable data insights, helping companies refine their processes and improve overall effectiveness.

Related Posts

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

Top Strategies for Choosing the Best Bag Filling Machine for Your Business

-

Exploring Cost Effective Alternatives to the Best Vertical Packaging Machine for Your Business

-

Top Strategies for Choosing the Best Food Packing Machine for Your Business

-

Common Challenges Faced by Buyers of the Best Automatic Packing Machine