Emerging Trends in Automatic Packaging Machines at the 2025 China 138th Import and Export Fair

At the 2025 China 138th Import and Export Fair, the spotlight will shine on the latest advancements in automatic packaging machines, a sector poised to revolutionize the manufacturing landscape. According to a report by Market Research Future, the global automatic packaging machine market is expected to reach approximately USD 60 billion by 2025, growing at a CAGR of around 9%. This growth is driven by the rising demand for efficient packaging solutions across various industries, including food, pharmaceuticals, and consumer goods. The fair will showcase state-of-the-art technologies such as smart packaging, robotics integration, and enhanced automation processes, which promise to optimize production lines and reduce operational costs. As businesses increasingly prioritize sustainability, innovations like biodegradable materials and energy-efficient machines will also be highlighted, reflecting the shifting dynamics towards environmentally friendly practices. The insights and developments presented at the fair will be crucial for industry professionals looking to stay ahead in this rapidly evolving market.

Emerging Technologies Driving Automatic Packaging Machines at the Fair

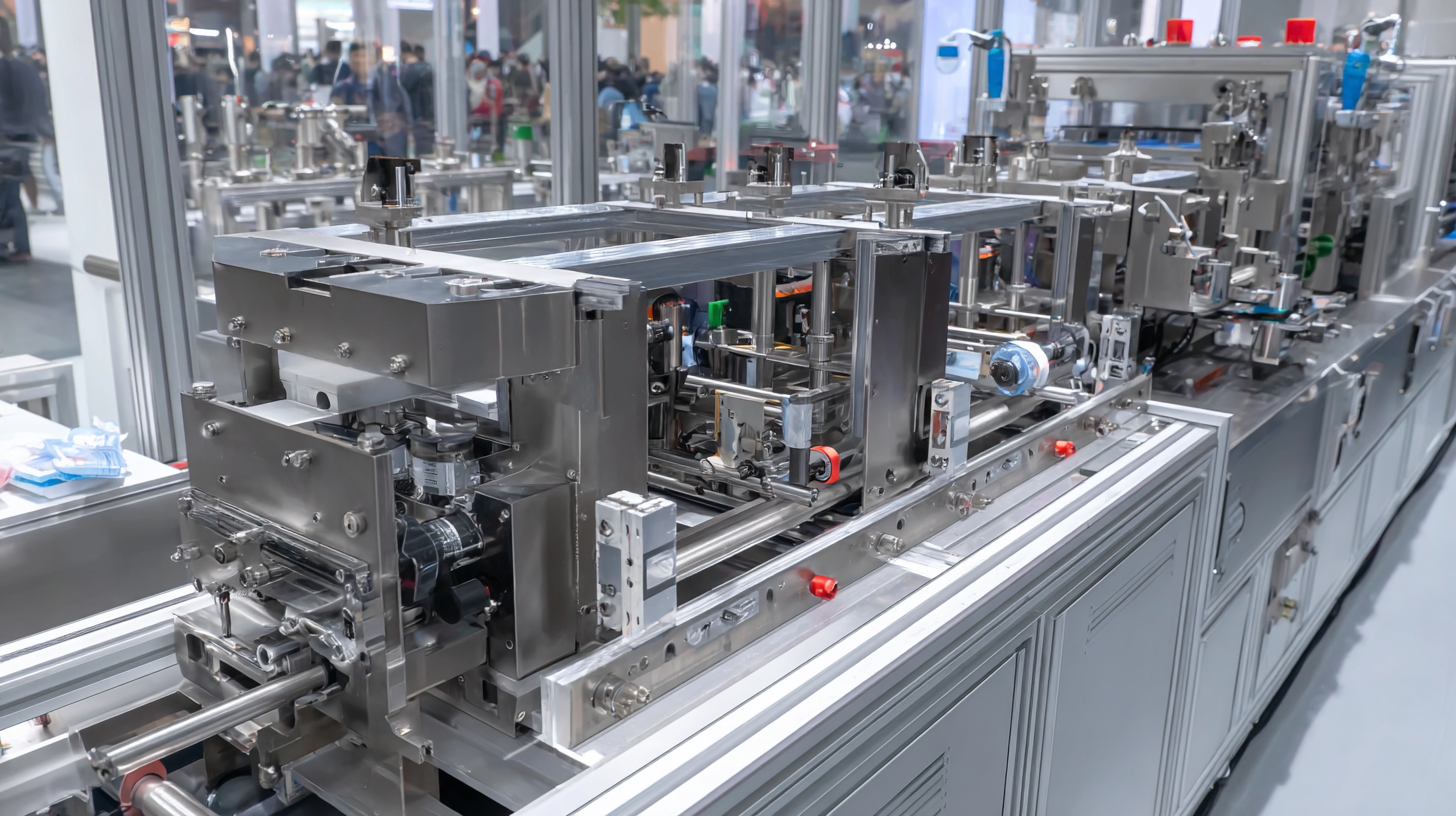

At the upcoming 2025 China 138th Import and Export Fair, the automatic packaging machines are set to showcase remarkable advancements driven by cutting-edge technologies. Among the emerging trends, the application of artificial intelligence is anticipated to play a crucial role in enhancing the efficiency and versatility of packaging processes. With the emphasis on innovation, businesses will demonstrate how integrating AI can optimize packaging lines, improving productivity while minimizing waste and operational costs.

Additionally, the introduction of servo technology in packaging machinery promises to revolutionize packaging operations. This technology not only increases automation but also enhances precision, ensuring that products are packaged securely and with minimal human intervention. The fair will feature numerous exhibitors presenting their latest models, including hygienic solutions tailored for various industries such as pharmaceuticals, cosmetics, and food. As these technologies evolve, they are expected to redefine the standards of performance and sustainability in the packaging sector, setting a new benchmark for both quality and efficiency.

Sustainability Innovations in Packaging Machinery on Display

The 2025 China 138th Import and Export Fair is set to be a showcase for groundbreaking sustainability innovations in packaging machinery, reflecting a growing trend towards eco-friendly practices in the industry. According to a report by Smithers Pira, the global sustainable packaging market is projected to reach $500 billion by 2027, with an annual growth rate of around 5.7%. This shift is fueled by increasing consumer demand for environmentally responsible products and regulatory pressures pushing manufacturers towards more sustainable practices.

At the fair, attendees can expect to see advanced automatic packaging machines that utilize biodegradable materials, energy-efficient technologies, and smart automation to reduce waste and enhance efficiency. For instance, companies like Tetra Pak have introduced packaging solutions that aim for a 50% reduction in carbon emissions by 2030. Additionally, the integration of IoT in packaging machinery is on the rise, allowing for real-time monitoring of resource use and waste management, which can lead to significant operational enhancements and sustainability benefits. The emphasis on innovation in packaging machinery not only highlights the industry's commitment to sustainability but also positions it as a key player in the global effort to combat climate change.

Impact of IoT and Automation on Packaging Efficiency

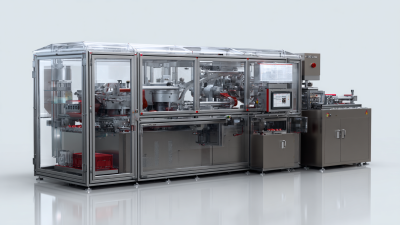

The 2025 China 138th Import and Export Fair presents an exciting opportunity to explore the latest advancements in automatic packaging machines, particularly the profound impact of IoT and automation on packaging efficiency. As industries strive for enhanced productivity, the integration of smart technologies is revolutionizing the packaging sector. IoT-enabled machines facilitate real-time monitoring of production lines, allowing for predictive maintenance and minimizing downtime. This connected system not only improves the operational efficiency but also enhances quality control, resulting in superior product packaging.

Tips for businesses looking to adopt these technologies include starting with a clear automation roadmap that identifies specific goals and desired outcomes. Additionally, investing in training for staff is crucial to ensure they are equipped to handle advanced machinery. It may also be beneficial to collaborate with technology vendors who understand both the packaging industry and the latest IoT advancements.

Furthermore, incorporating automation in packaging processes can significantly reduce labor costs and speed up the overall production time. By utilizing robotic systems for repetitive tasks, companies can free up human resources for more complex functions that require creativity and problem-solving skills. This balance between technology and human expertise is essential for successful implementation in modern packaging operations.

Emerging Trends in Automatic Packaging Machines at the 2025 China 138th Import and Export Fair

This chart illustrates the impact of IoT and automation on packaging efficiency from 2020 to 2025, showcasing the increase in efficiency percentages across different packaging sectors.

Trends in Customization and Flexibility of Packaging Machines

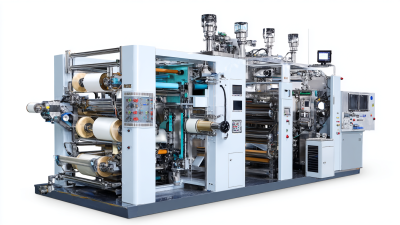

The 2025 China 138th Import and Export Fair is set to showcase significant advancements in the realm of automatic packaging machines, particularly emphasizing customization and flexibility. Recent reports from the International Packaging Association highlight a growing demand for tailored packaging solutions, with 52% of manufacturers stating that customizable packaging options are crucial for meeting diverse consumer needs. The ability to adapt packaging processes efficiently not only enhances operational agility but also allows companies to respond swiftly to changing market trends.

Furthermore, the trend toward flexible packaging machinery is gaining momentum, as businesses seek to optimize production lines for a variety of products. According to a Global Market Insights report, the flexible packaging machinery market is projected to reach $36 billion by 2026, growing at a CAGR of 4.5% from 2021 to 2026. This shift is driven by the rise of e-commerce and the increasing demand for sustainable packaging solutions. As manufacturers invest in advanced technologies that enable quick changeovers and integrate smart automation, they are better positioned to cater to personalized consumer experiences and enhance overall efficiency in their operations.

Market Insights: Future of Packaging Solutions Post-Fair

The 2025 China 138th Import and Export Fair is set to spotlight innovative trends in automatic packaging machines, signaling a transformative shift in the packaging landscape. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach $60 billion by 2027, driven by advancements in automation and increased demand for efficiency. This trend is particularly vital in sectors such as food and beverages, pharmaceuticals, and consumer goods, where swift and reliable packaging solutions are paramount.

Post-fair insights suggest that companies will increasingly invest in eco-friendly packaging technologies and smart automation. According to a recent study by MarketsandMarkets, the smart packaging market is anticipated to grow from $27.4 billion in 2020 to $45.4 billion by 2025, with automatic packaging machines playing a critical role. As industry players seek to meet consumer demands for sustainability and personalization, strategies emerging from the fair will likely focus on integrating IoT capabilities and sustainable materials in their packaging systems, enhancing both operational efficiency and environmental responsibility.

Related Posts

-

Embracing Innovation in 2025 How Best Automatic Packing Machines Will Transform Global Supply Chains

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Innovative Solutions for Food Packaging Machine Efficiency and Quality

-

7 Compelling Reasons Your Business Needs an Automatic Packaging Machine Today

-

Common Challenges Faced by Buyers of the Best Automatic Packing Machine

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines