Unlocking Efficiency: Why a Filling Machine is Essential for Modern Manufacturing

In the fast-paced world of modern manufacturing, efficiency and precision are paramount, making the filling machine an indispensable asset across various industries. According to a report by MarketsandMarkets, the global filling machine market is projected to grow from USD 5.2 billion in 2020 to USD 7.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This remarkable growth underscores the increasing demand for automated solutions that enhance production capabilities, reduce labor costs, and improve consistency in product quality. As manufacturers face rising consumer expectations and stringent regulatory standards, adopting advanced filling machines not only streamlines operations but also contributes to maximizing output efficiency. In an era where agility and responsiveness are crucial for competitive advantage, the strategic implementation of filling machines is reshaping the landscape of modern manufacturing.

The Role of Filling Machines in Streamlining Production Processes

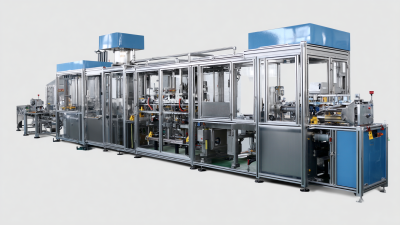

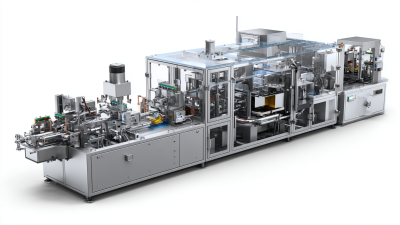

Filling machines play a pivotal role in modern manufacturing, particularly in industries such as food and beverage, pharmaceuticals, and cosmetics. By automating the filling process, these machines significantly reduce production time and minimize human error, leading to a more efficient workflow. As businesses strive to meet increasing consumer demands, the integration of advanced filling machines helps streamline production processes while ensuring product consistency and quality.

Tip: Ensure proper calibration of your filling machine before operation to maintain accuracy. Regularly check measurements to confirm that each product is filled to specification.

The versatility of filling machines allows them to handle a wide range of products, from liquids to powders, while accommodating various container types. This adaptability is crucial for manufacturers as it enables them to diversify their offerings without investing in multiple machines. Additionally, modern filling machines often come equipped with advanced technology, such as sensors and PLC controls, to provide real-time monitoring and adjustments.

Tip: Invest in a maintenance schedule for your filling machines to prevent unexpected downtime. Regular maintenance can prolong the life of the equipment and maintain production efficiency.

Key Advantages of Automated Filling Technology in Modern Factories

The adoption of automated filling technology in modern manufacturing is transforming the efficiency and productivity of production lines. As businesses strive for faster turnaround times and higher accuracy, filling machines play a pivotal role in streamlining processes. By minimizing human intervention, these machines not only reduce the risk of errors but also enhance the consistency of product quality. With the global liquid filling machine market expected to grow from $6.82 billion in 2025 to $10.39 billion by 2032, the demand for automated solutions is on the rise, reflecting a broader shift in manufacturing towards greater automation.

Moreover, automated filling technology offers significant advantages in terms of scalability and adaptability. Manufacturers can easily adjust their filling systems to accommodate various container sizes and liquid types, ensuring flexibility in production. This adaptability is crucial in today’s fast-paced market, where companies must respond swiftly to changing consumer preferences. The integration of smart technologies, such as IoT and AI, further enhances the capabilities of filling machines, allowing for real-time monitoring and optimization of production processes. As a result, modern factories that implement these automated solutions can achieve higher efficiency and improved operational performance.

Unlocking Efficiency: Key Advantages of Automated Filling Technology

Enhancing Product Consistency: The Impact of Filling Machines on Quality Control

Filling machines play a crucial role in modern manufacturing by significantly enhancing product consistency, which is vital for effective quality control. In industries where precise quantities are essential, these machines ensure that each container is filled to the required level, minimizing human error and variations. This uniformity is not only critical for maintaining standards but also impacts customer satisfaction. When consumers receive products that meet their expectations in consistency, it builds brand loyalty and trust.

Moreover, the integration of advanced technologies in filling machines has further improved their precision. Features such as weight controllers and automated sensors allow for real-time adjustments during the filling process, reducing the likelihood of underfills or overfills. This automation not only streamlines production but also decreases waste, leading to cost savings. As a result, manufacturers can achieve higher efficiency and quality, ensuring that their products meet regulatory standards and consumer expectations consistently.

Cost Savings Through Increased Efficiency: A Closer Look at Filling Machine Benefits

In today's fast-paced manufacturing landscape, efficiency is paramount for maintaining competitiveness. Filling machines play a crucial role in optimizing production lines by reducing the time and labor required for filling products. This automation not only streamlines operations but also minimizes human error, leading to more consistent product quality. By integrating filling machines, manufacturers can significantly enhance throughput, allowing for faster delivery times while meeting consumer demand.

Moreover, the cost savings associated with filling machines extend beyond labor reduction. These machines consume fewer resources in terms of materials and energy, leading to a decrease in overall operational costs. Their precision in filling helps mitigate waste, ensuring that every drop of the product is accounted for, which is particularly beneficial in industries where material costs are high. With improved efficiency and reduced waste, businesses are not only saving money but are also contributing to more sustainable manufacturing practices. The investment in filling machines therefore represents a strategic choice that supports both profitability and environmental responsibility.

Future Trends: Innovations in Filling Machinery for Advanced Manufacturing

The landscape of modern manufacturing is rapidly evolving, particularly with the integration of innovative filling machinery designed to enhance productivity and precision. Future trends in filling technology are heavily focused on automation and smart systems, which utilize artificial intelligence and machine learning to optimize operations. These advancements enable manufacturers to achieve greater accuracy in filling processes, reduce waste, and improve overall efficiency. As production demands increase, the need for rapid changeovers and flexibility in filling lines becomes crucial, prompting manufacturers to invest in adaptable machinery that can seamlessly handle various product types and sizes.

In addition, sustainability is becoming a key driver in the innovation of filling machinery. Companies are increasingly prioritizing eco-friendly practices, leading to the development of machines that minimize energy consumption and utilize recyclable packaging materials. Emerging technologies such as IoT sensors allow for real-time monitoring of production processes, enabling manufacturers to make informed decisions that align with sustainability goals. As the industry progresses, the synergy between innovation, efficiency, and environmental responsibility will define the future of filling machinery, ensuring that it remains an essential component of advanced manufacturing.

Related Posts

-

How to Choose the Right Filling Machine for Your Production Needs

-

The Ultimate Guide to Choosing the Best Filling Machine for Your Production Needs

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

Leading the World with Chinas Best Bag Filling Machine Innovation

-

Exploring the Unique Features and Applications of the Best Form Fill Seal Machines: A Complete Guide

-

Ultimate Checklist: Top Features to Look For in the Best Bag Filling Machine