Flow Wrap Machines: An In-Depth Comparison of Features, Costs, and Performance

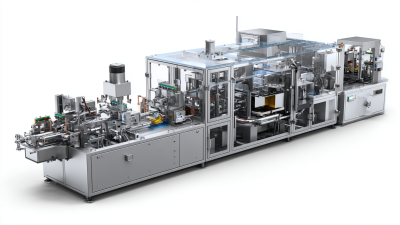

In the fast-paced world of packaging, the choice of equipment can significantly impact productivity and product quality. Among the various packaging solutions available, the flow wrap machine stands out for its versatility and efficiency in wrapping products such as snacks, bakery items, and consumer goods. As businesses seek to optimize their packaging processes, it becomes crucial to understand the different types of flow wrap machines on the market. This blog aims to provide an in-depth comparison of the features, costs, and performance of flow wrap machines, enabling manufacturers to make informed decisions tailored to their specific needs.

By exploring various examples and applications, we will illuminate how these machines can enhance operational efficiency and improve the overall packaging experience. Join us as we delve into the intricacies of flow wrap machinery and discover the best options available for your packaging requirements.

Key Features to Look for in Flow Wrap Machines

When considering the purchase of a flow wrap machine, several key features are essential to ensure optimal performance for your packaging needs. One of the most critical aspects is the machine’s speed and efficiency. Look for models that can handle a high volume of products per minute without compromising on quality. Additionally, consider the versatility of the machine – it should be capable of packaging various product sizes and shapes with ease.

Another important feature to evaluate is the ease of use and maintenance of the flow wrap machine. User-friendly interfaces and automated settings can significantly reduce operational errors and downtime. Ensure that the machine is designed for quick setup and changeovers, which can save valuable time in a fast-paced production environment.

Tip: When assessing potential machines, request demonstrations to see their features in action. Inquire about the technical support provided by the manufacturer, as this can be crucial in minimizing interruptions. Additionally, consider the energy efficiency of the machine, as more efficient models can reduce operational costs over time.

Comparing Cost-effectiveness of Different Flow Wrap Machines

When investing in flow wrap machines, understanding cost-effectiveness is crucial. Different models come with varying features that can significantly influence overall expenses. It's essential to evaluate not only the initial purchase price but also the long-term operating costs, including maintenance, energy consumption, and labor. For example, some machines might have higher upfront costs but offer advanced technology that enhances speed and efficiency, leading to greater savings over time.

Tip: Consider the total cost of ownership (TCO) by factoring in potential downtime and repair costs associated with each machine. Investing in a higher-quality unit could save you from unexpected expenses down the line.

Another factor to consider is the versatility of the flow wrap machine. Machines that can handle a wider range of product sizes and types tend to be more cost-effective. They allow for more flexibility in production runs without the need for multiple machines. Additionally, the ability to easily switch between packaging styles can optimize workflow and reduce waste.

Tip: Before making a decision, assess your current and future production needs to choose a machine that can grow with your business, ensuring you maximize value for your investment.

Performance Metrics: How to Evaluate Flow Wrap Machines

When evaluating flow wrap machines, performance metrics are crucial in ensuring that the chosen equipment meets production needs. Key factors to consider include speed, flexibility, and accuracy. The processing speed, measured in packages per minute, directly impacts overall efficiency and productivity. Therefore, select a machine that can adapt to your desired output without compromising on quality.

Tips for assessing flexibility include examining how easily the machine can switch between different packaging sizes and materials. A versatile flow wrap machine saves time and resources, especially in dynamic production environments. Additionally, evaluate the accuracy of the wrapping process, as improper sealing can lead to product damage and increased waste.

To further enhance your decision-making, consider conducting a cost-benefit analysis. Analyze not only the initial purchase cost but also maintenance expenses, energy consumption, and the potential for increased productivity. This comprehensive understanding of the performance metrics will help you make an informed choice, ultimately leading to a successful packaging operation.

Flow Wrap Machines: An In-Depth Comparison of Features, Costs, and Performance

| Feature/Metric | Machine A | Machine B | Machine C |

|---|---|---|---|

| Speed (packages/min) | 120 | 100 | 150 |

| Film Width (mm) | 300 | 250 | 400 |

| Power Consumption (kW) | 5.5 | 6.0 | 4.8 |

| Dimensions (L x W x H, mm) | 2000 x 800 x 1200 | 1800 x 700 x 1100 | 2200 x 850 x 1300 |

| Weight (kg) | 450 | 420 | 500 |

| Cost ($) | 25,000 | 22,000 | 30,000 |

Top Brands and Models in the Flow Wrap Machine Market

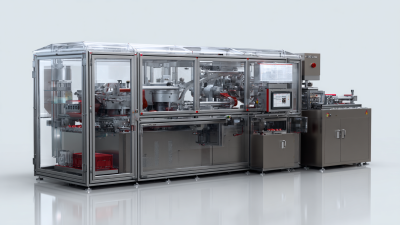

In the competitive landscape of the flow wrap machine market, several brands and models have established themselves as leaders, each offering unique features and performance metrics. Companies like Bosch, Omori, and Ilapak are renowned for their innovative designs and reliability.

Bosch, with its advanced technology, focuses on speed and efficiency, making it ideal for high-volume production environments. On the other hand, Omori offers customizable solutions, allowing businesses to tailor machines according to their specific packaging needs. This flexibility has made Omori a popular choice among smaller operators looking to optimize their processes.

Moreover, Ilapak stands out with its focus on sustainability and eco-friendly designs, appealing to businesses prioritizing environmental responsibility. Their machines not only provide excellent packaging performance but also reduce material waste. Each of these brands brings something distinct to the table, whether it's efficiency, customization, or sustainability, giving businesses the variety needed to match machine capabilities with their production goals.

As companies navigate their options, understanding the strengths of these top models will aid in making informed decisions to enhance their packaging operations.

Customer Reviews: Real Experiences with Flow Wrap Machines

In the rapidly evolving landscape of flow wrap machines, customer feedback plays a pivotal role in shaping product development and service offerings. A recent report highlights that 72% of businesses believe that customer experience is a key differentiator in gaining competitive advantage. This trend emphasizes the need for manufacturers to not only focus on the performance features of their machines but also prioritize customer-centric support services.

Many users have shared their experiences, pointing to the significance of reliability and efficiency in their operations. Statistics reveal that 65% of users reported significant productivity improvements after switching to newer flow wrap machines with enhanced automation features. Additionally, customer insights indicate that while upfront costs are important, the long-term ROI driven by lower maintenance and operational costs greatly influences purchasing decisions. This customer-centric approach aligns with the findings in the digital era, where engaging with customer feedback leads to innovative solutions tailored to real-world needs, thereby enhancing overall satisfaction and loyalty.

Related Posts

-

How to Choose the Best Wrapping Machine by Understanding Key Technical Specifications and Features

-

Exploring the Unique Features and Applications of the Best Form Fill Seal Machines: A Complete Guide

-

Discover World Class Manufacturing with the Best Flow Wrap Machine from China

-

7 Top Benefits of the Best Form Fill Seal Machine for Global Buyers

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines