Innovative Solutions for Food Packaging Machine Efficiency and Quality

The food packaging machine industry is undergoing a significant transformation driven by the demand for increased efficiency and quality in food preservation. According to a report by MarketsandMarkets, the global food packaging market is projected to reach $500 billion by 2025, with a compound annual growth rate (CAGR) of 5.1%. This growth is fueled by changing consumer preferences towards convenience, sustainability, and enhanced food safety. As a result, food packaging machines are now being equipped with advanced technologies such as automation, smart sensors, and eco-friendly materials that not only optimize production processes but also minimize waste.

In this blog, we will explore innovative alternatives that are redefining the capabilities of food packaging machines, addressing the challenges faced by manufacturers while meeting the evolving demands of consumers and regulatory bodies alike.

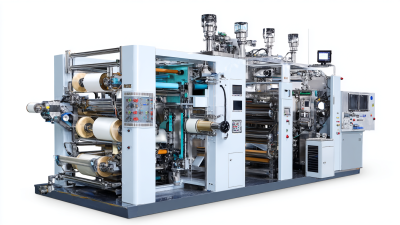

Maximizing Efficiency: The Role of Automation in Food Packaging Machines

The integration of automation in food packaging machines has revolutionized the industry, enhancing both efficiency and product quality. Automation technologies such as robotic arms and advanced sensors streamline the packaging process, significantly reducing the time required to package food items. This leads to higher output rates, allowing manufacturers to meet increasing demand without sacrificing quality. By minimizing human intervention, automated systems not only reduce the risk of errors but also ensure consistent packaging standards, which is crucial for maintaining food safety and integrity.

Moreover, automated food packaging machines are equipped with intelligent software that optimizes production lines. These systems can swiftly adjust to different packaging requirements, ensuring flexibility in operations. By utilizing real-time data analytics, manufacturers can monitor performance metrics and quickly identify bottlenecks, enabling proactive decision-making. This adaptability not only boosts efficiency but also contributes to sustainable practices by reducing waste and energy consumption. Ultimately, embracing automation in food packaging is a key strategy for companies looking to enhance productivity while maintaining high-quality standards.

Critical Factors Affecting Food Packaging Quality

When it comes to food packaging, quality is paramount. Critical factors that affect food packaging quality include the materials used, sealing techniques, and environmental considerations. The selection of packaging materials plays a significant role; they must provide barriers against moisture, oxygen, and contaminants while being safe for food contact. Innovations in materials, such as biodegradable films and smart packaging solutions, not only enhance quality but also cater to the growing consumer demand for sustainability.

Another crucial factor is the sealing process. Effective sealing methods prevent leakage and preserve the freshness of the food, which is essential for maintaining quality during storage and transportation. Advanced technologies like vacuum sealing or modified atmosphere packaging help extend shelf life and improve the overall product integrity. Furthermore, businesses must consider environmental conditions, as factors such as temperature and humidity during storage and shipping can impact the packaged food's quality. By addressing these critical aspects, manufacturers can optimize their food packaging processes and ensure that their products meet the highest quality standards.

Integrating Smart Technology for Enhanced Packaging Solutions

The integration of smart technology in food packaging is revolutionizing the industry by enhancing efficiency and quality. As we witness the rise of Packaging 4.0, key technologies such as artificial intelligence (AI), the Internet of Things (IoT), blockchain, and robotics are leading the charge. These advancements not only streamline packaging processes but also ensure product integrity and sustainability. For instance, AI algorithms can optimize packaging design, while IoT sensors monitor conditions throughout the supply chain, providing real-time data that enhances decision-making and reduces waste.

Smart packaging is particularly vital in promoting transparency within the supply chain. Utilizing IoT sensors, QR codes, and RFID tags, companies can track products from production to delivery, providing consumers with detailed information about the origins and handling of their food. This technology not only boosts consumer trust but also aids retailers and manufacturers in adhering to regulatory standards. With projections indicating significant growth in the smart packaging market for retail and e-commerce, the future looks bright for innovations that prioritize not just efficiency, but also the overall safety and experience of consumers.

Innovative Solutions for Food Packaging Machine Efficiency and Quality

| Dimension | Metric | Value | Comments |

|---|---|---|---|

| Production Speed | Packages per Minute | 120 | Optimized for high throughput |

| Energy Consumption | kWh per Hour | 15 | Low energy usage |

| Material Waste | Percentage | 2% | Efficient material usage |

| Maintenance Frequency | Times per Year | 4 | Scheduled maintenance |

| Quality Failure Rate | Percentage | 0.5% | High quality assurance |

| Downtime | Hours per Month | 2 | Minimized interruptions |

Sustainable Practices in Food Packaging: Balancing Efficiency and Environment

Sustainable practices in food packaging are becoming increasingly essential as consumers demand more environmentally friendly options. The integration of eco-friendly materials, such as biodegradable plastics made from renewable resources, allows manufacturers to reduce their carbon footprint while maintaining product integrity. These materials not only provide adequate protection for food but also break down more quickly than traditional plastics, minimizing long-term waste in landfills. By embracing these alternatives, businesses can create a positive impact on the environment without sacrificing the efficiency of their packaging processes.

Moreover, innovative machinery plays a crucial role in promoting sustainability in food packaging. Modern food packaging machines are designed to optimize material usage and reduce energy consumption. Automatic and smart technologies can adjust the packaging process in real-time, ensuring minimal waste during operation. For instance, machines that utilize adjustable cutting and sealing techniques can cater to various package sizes, significantly cutting down on excess materials and improving overall efficiency. This evolution in technology not only enhances the quality of packaging but also aligns with the growing demand for sustainable practices, creating a win-win situation for both the industry and the planet.

Best Practices for Maintenance and Troubleshooting in Packaging Machines

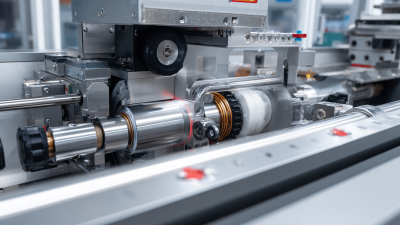

In the ever-evolving landscape of food packaging, maintaining the efficiency and quality of packaging machines is paramount. According to a recent report by the Food Processing Machinery Association, nearly 85% of packaging machine failures stem from inadequate maintenance practices. Regular maintenance not only improves operational efficiency but also extends the lifespan of these machines. Implementing a robust maintenance schedule, which includes routine inspections and timely replacement of worn parts, can significantly reduce downtime and increase productivity.

Troubleshooting is equally crucial in ensuring the seamless operation of packaging machines. A survey by the International Packaging Association found that up to 70% of common packaging issues, such as product contamination and sealing defects, can be traced back to operator error or lack of training. Investing in comprehensive training for operators can mitigate these issues, enhancing product quality and compliance with safety standards. Furthermore, utilizing smart technology for real-time monitoring can identify potential problems before they escalate, fostering a proactive approach to machine management and ensuring a high standard of packaging quality.

Related Posts

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Top Strategies for Sourcing the Best Food Packing Machine Globally

-

Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine

-

How to Choose the Right Food Packing Machine for Your Business Needs

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

Discover Excellence in Manufacturing with the Leading Horizontal Packaging Machine from Top Chinese Factory