The Impact of Plastic Wrapping Machines on Sustainable Packaging Solutions

In an era where sustainability has become a paramount concern for industries worldwide, the role of technology in facilitating eco-friendly packaging solutions cannot be underestimated. The plastic wrapping machine, a vital tool in modern packaging processes, plays a crucial role in enhancing efficiency while also addressing environmental goals. According to a report by Smithers Pira, the global demand for sustainable packaging is projected to reach $500 billion by 2026, driven largely by consumer preferences for eco-conscious products. These machines not only optimize the use of packaging materials but also reduce waste through innovative designs that minimize the amount of plastic used without compromising product integrity.

By integrating smart technologies that enable better material management and recycling options, plastic wrapping machines are paving the way for a more sustainable future in packaging, thus aligning with the growing imperative for businesses to adopt greener practices.

Understanding the Role of Plastic Wrapping Machines in Sustainable Packaging

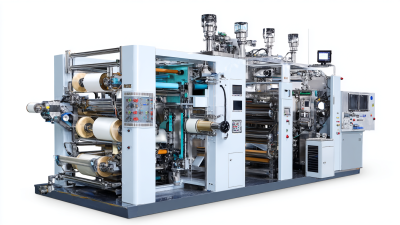

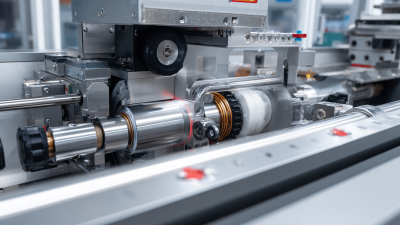

Plastic wrapping machines play a pivotal role in advancing sustainable packaging solutions by enhancing efficiency and reducing waste. These machines are designed to optimize the amount of plastic used for wrapping products, ensuring that packaging is secure without contributing to excessive material consumption. By incorporating technologies such as automatic film cutting and precise wrapping techniques, manufacturers can minimize plastic waste and streamline the packaging process, leading to a more sustainable production cycle.

Moreover, the integration of biodegradable and recyclable film materials into plastic wrapping machines further supports sustainable practices. As companies shift towards eco-friendly alternatives, the adaptability of these machines allows businesses to implement sustainability measures without compromising on functionality. Additionally, the energy-efficient operation of modern plastic wrapping machines contributes to reducing the overall carbon footprint of packaging processes. This dual focus on efficiency and sustainability showcases how plastic wrapping machines can be a crucial component in the quest for environmentally responsible packaging solutions.

Evaluating the Environmental Benefits of Using Plastic Wrapping Technology

The use of plastic wrapping technology is gaining traction as a sustainable packaging solution, primarily due to its efficiency and versatility. These machines optimize the packaging process by reducing material waste, as they enable precise control over the amount of plastic used. By ensuring that products are tightly wrapped, they also contribute to reducing spoilage and extending shelf life, which is crucial in reducing food waste. This reduction in waste not only benefits businesses by lowering costs but also contributes to broader environmental sustainability efforts.

Furthermore, advancements in plastic wrapping machines have led to the development of biodegradable and recyclable films. This shift towards environmentally friendly materials is significant, as it aligns with global efforts to mitigate plastic pollution. The integration of such materials into the wrapping process allows companies to maintain the protective qualities of plastic while minimizing their ecological footprint. By adopting these technologies, industries can play a pivotal role in promoting more sustainable practices, ultimately fostering a greener future.

The Impact of Plastic Wrapping Machines on Sustainable Packaging Solutions - Evaluating the Environmental Benefits of Using Plastic Wrapping Technology

| Dimension | Impact | Measurement | Notes |

|---|---|---|---|

| Reduction in Packaging Waste | 30% reduction | Tons per year | Based on industry averages |

| Energy Consumption | 15% less energy used | Kilowatt-hours | Compared to traditional methods |

| Carbon Footprint | 20% lower emissions | CO2 equivalent | Based on lifecycle analysis |

| Recyclability | Up to 80% recyclable | Percentage | Depends on material quality |

| Cost Savings | 10% reduction in costs | Annual savings | Based on operational efficiency |

Integrating Eco-Friendly Materials with Plastic Wrapping Machines

The integration of eco-friendly materials with plastic wrapping machines is an essential step towards improving sustainability in packaging solutions. Traditional plastic packaging has been a significant contributor to environmental pollution, leading industries to seek alternatives that minimize ecological footprints. By incorporating biodegradable or recyclable materials into the packaging process, companies can leverage advanced wrapping machines that are designed to handle these sustainable inputs without compromising efficiency or product integrity.

Moreover, the adoption of eco-friendly materials fosters innovation within the packaging industry. Manufacturers are increasingly experimenting with various bioplastics and compostable films that not only match the durability and protection levels of conventional plastics but also degrade naturally over time. This shift not only enhances a company's brand image but also meets the growing consumer demand for responsible packaging.

As plastic wrapping machines become more versatile in accommodating these materials, the potential for reducing waste and promoting sustainability becomes more viable, paving the way for a greener future in packaging.

Strategies for Optimizing Packaging Processes for Sustainability

In today's eco-conscious market, optimizing packaging processes for sustainability is essential, especially with the advent of advanced plastic wrapping machines. According to the 2023 Smithers report on sustainable packaging, the global market for sustainable packaging is expected to reach $1 trillion by 2024, driven by consumer demand for environmentally friendly solutions. By incorporating energy-efficient plastic wrapping machines, companies can significantly reduce their carbon footprint while maintaining product integrity. These machines not only minimize waste but also enhance production efficiency, aligning with sustainable business practices.

To further enhance sustainability, businesses should focus on materials and techniques that limit environmental impact. Utilizing biodegradable films and recyclable materials in conjunction with modern wrapping technologies can lead to a significant decrease in plastic pollution. Additionally, a 2023 survey by the Packaging Association revealed that 63% of companies investing in sustainable packaging solutions saw a marked improvement in their brand image and customer loyalty. By adopting strategies such as lightweight packaging design and optimizing material usage, companies can achieve robust sustainability goals while meeting regulatory requirements and enhancing consumer trust.

The Impact of Plastic Wrapping Machines on Sustainable Packaging Solutions

This bar chart illustrates the impact of plastic wrapping machines on key sustainable packaging metrics, showcasing areas such as material reduction, recyclability, energy efficiency, waste minimization, and cost efficiency. The data reflects the potential improvements in each dimension as organizations adopt more sustainable packaging processes.

Future Trends in Plastic Wrapping Solutions and Their Environmental Impact

The evolution of plastic wrapping machines is significantly reshaping sustainable packaging solutions, with an increasing focus on minimizing environmental impact. According to a report by the Sustainable Packaging Coalition, the global market for sustainable packaging is projected to reach $600 billion by 2027, driven largely by consumer demand for eco-friendly alternatives. As technology advances, modern plastic wrapping machines are becoming more efficient, utilizing thinner films that reduce material usage without compromising product protection.

Future trends indicate a shift towards biodegradable and compostable films, aligning with the circular economy model. Research from Smithers Pira highlights that the demand for biodegradable materials will grow at an annual rate of 20% through 2025. Additionally, innovations such as water-soluble packaging are gaining traction, with companies like BASF investing heavily in this area. These trends not only address consumer preferences for sustainable options but also significantly reduce landfill waste, contributing to a more sustainable future in the packaging industry.

Related Posts

-

How to Choose the Best Wrapping Machine by Understanding Key Technical Specifications and Features

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine

-

Innovative Solutions for Food Packaging Machine Efficiency and Quality

-

Maximizing Efficiency with Advanced Wrapping Machine Solutions

-

7 Effective Tips for Choosing the Right Food Packing Machine