Maximizing Efficiency with Advanced Wrapping Machine Solutions

In today's fast-paced manufacturing environment, maximizing efficiency is paramount for companies striving to maintain competitive advantage. Advanced wrapping machine solutions play a crucial role in streamlining operations, enhancing productivity, and ensuring product integrity. According to a recent report by MarketsandMarkets, the wrapping machine market is projected to grow from $4.5 billion in 2021 to $6.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.0%. This growth underscores the increasing reliance on automated wrapping systems to meet consumer demand and improve supply chain efficiency. By implementing top strategies for optimizing these wrapping machines, businesses can significantly reduce labor costs, minimize material waste, and improve the overall packaging process. As we delve into the best practices for leveraging advanced wrapping technology, we will explore how companies can enhance their operational effectiveness and achieve sustainable growth in an increasingly competitive landscape.

The Evolution of Wrapping Machines: Trends Shaping the Future

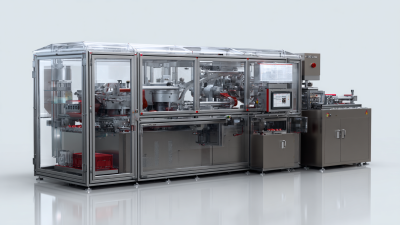

The evolution of wrapping machines has significantly impacted various industries, leading to increased efficiency and productivity. In recent years, technological advancements have introduced automation and smart capabilities that enable these machines to adapt to diverse packaging needs. From simple manual machines to complex automated solutions, the journey reflects a continuous pursuit of optimization and cost-effectiveness.

One notable trend shaping the future of wrapping machines is the incorporation of Artificial Intelligence (AI) and machine learning. These technologies allow machines to learn from previous operations, thus optimizing wrapping processes and reducing waste. For businesses looking to enhance their packaging system, investing in an AI-driven wrapping machine could yield substantial long-term benefits.

Tip: When considering a new wrapping machine, assess its compatibility with your current workflow to ensure a smooth integration. Additionally, prioritize machines that offer programmable features, allowing operators to switch between different packaging styles with ease. By aligning your wrapping solutions with market trends, you can not only improve efficiency but also stay ahead of competitors.

Key Benefits of Automation in Wrapping Processes for Efficiency

In today's fast-paced manufacturing environment, automation in wrapping processes has become essential for maximizing efficiency. Advanced wrapping machines streamline production flows, reduce manual labor, and minimize errors. By integrating automated solutions, companies can achieve a significant increase in throughput while maintaining high-quality standards.

Tip: Evaluate the specific needs of your production line before selecting a wrapping machine. Consider factors such as product dimensions and material types, as these will influence the efficiency gains you can achieve. Selecting a machine designed for your unique requirements ensures optimal performance.

Automation not only speeds up wrapping processes but also enhances data collection for improved decision-making. With real-time monitoring, operators can identify bottlenecks and adjust workflows accordingly. This adaptability allows for better resource allocation and more efficient project timelines.

Tip: Invest in training your team on the new automated systems. Proper knowledge and operational skills can lead to smoother transitions and more effective use of machinery, ultimately increasing your return on investment.

Industry Statistics: How Advanced Wrapping Solutions Enhance Productivity

In today's fast-paced manufacturing environment, advanced wrapping solutions have proven to significantly enhance productivity across various sectors. According to recent industry reports, the Packaging Automation Market is projected to rise to USD 52.2 billion, driven by an increasing demand for efficiency, precision, and reduced labor. These advanced wrapping machines not only streamline operations but also integrate smart technologies that optimize the packaging process. By adopting such solutions, companies can minimize errors and waste, ultimately leading to higher output and lower operational costs.

Moreover, the integration of artificial intelligence and machine learning into packaging systems is transforming productivity levels. Research indicates that more than 66% of CEOs recognize AI's potential to reshape their industries, particularly in enhancing supply chain management. By employing deep learning techniques, businesses can improve inventory control and production efficiency, further amplifying the benefits of using advanced wrapping technologies. As industries adapt to these innovative solutions, the focus on sustainability and efficiency will remain vital in maximizing overall productivity within the market.

Maximizing Efficiency with Advanced Wrapping Machine Solutions - Industry Statistics

| Category | Metric | Value | Percentage Improvement |

|---|---|---|---|

| Cycle Time Reduction | Average Cycle Time | 2.5 minutes | 30% |

| Productivity Increase | Units Wrapped per Hour | 200 units | 40% |

| Labor Savings | Labor Hours per Day | 4 hours | 25% |

| Material Utilization | Material Waste | 10% | 15% |

| Machine Downtime | Downtime per Week | 5 hours | 50% |

Sustainability in Packaging: Eco-Friendly Options in Modern Wrappers

As the global focus on sustainability intensifies, modern wrapping machines are evolving to meet eco-friendly packaging demands. These advanced solutions not only enhance efficiency in production lines but also prioritize environmental stewardship. The integration of biodegradable materials in wrapping machines allows manufacturers to reduce their carbon footprint significantly. With options like compostable films and recyclable laminates, companies can now package their products while aligning with sustainable practices.

Moreover, innovative wrapping technologies enable businesses to minimize waste. Machines equipped with precise cutting and wrapping capabilities ensure that materials are utilized optimally, thereby reducing excess. This shift towards resource-efficient processes is essential for manufacturers aiming to meet stricter regulations and consumer expectations for sustainability. By embracing these eco-friendly options, companies can create packaging that is not only functional but also reflects a commitment to a greener planet, ultimately benefiting both the environment and their brand reputation.

Technological Innovations: The Role of AI and Robotics in Packaging Efficiency

The landscape of packaging efficiency is undergoing a profound transformation, primarily driven by technological innovations in artificial intelligence (AI) and robotics. These advancements are reshaping the way businesses approach wrapping and packing processes, allowing for unprecedented levels of precision and speed. For instance, AI algorithms are now capable of learning from historical data to predict optimal packing strategies. This not only reduces material waste but also ensures that resources are utilized to their fullest extent.

Robotics plays a pivotal role in this evolution, providing the necessary physical support to automate repetitive tasks. Advanced wrapping machines equipped with robotic arms can efficiently handle a variety of packaging materials, adapting seamlessly to different shapes and sizes. This flexibility not only enhances productivity but also minimizes human error, which is crucial in maintaining quality control. As a result, businesses leveraging these advanced wrapping solutions are able to respond quickly to market demands while maintaining high standards of efficiency and consistency in their operations.

Related Posts

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

Emerging Trends in Food Packaging Technology 2025 Your Ultimate Guide to the Best Food Packing Machines

-

Innovative Solutions for Food Packaging Machine Efficiency and Quality

-

The Ultimate Guide to Choosing the Right Food Packaging Machine for Your Business Needs

-

The Evolution of Pouch Filling Machines Shaping the Future of Packaging Industry

-

7 Top Benefits of the Best Form Fill Seal Machine for Global Buyers