Unveiling the Future: How Plastic Wrapping Machines Are Revolutionizing Packaging Efficiency

The rapid evolution of packaging technology has ushered in a new era of efficiency, prominently highlighted by the rise of the plastic wrapping machine. According to a recent report by Smithers Pira, the global flexible packaging market is projected to reach $348.66 billion by 2024, reflecting a compound annual growth rate of 4.4%. This surge is largely fueled by advancements in automation and the increasing demand for sustainable packaging solutions. Plastic wrapping machines play a pivotal role in this transformation, streamlining production lines and reducing material waste. Furthermore, a study by the Packaging Machinery Manufacturers Institute indicated that automating packaging processes can enhance efficiency by up to 30%, a critical factor for manufacturers striving to meet rising consumer expectations while minimizing costs. As industries increasingly embrace these innovations, the future of packaging efficiency appears more promising than ever.

Exploring the Role of Automation in Plastic Wrapping Machines

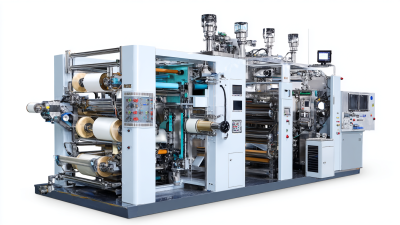

The integration of automation in plastic wrapping machines is dramatically transforming the packaging industry. Reports indicate that automated packaging solutions can improve efficiency by up to 30%, significantly reducing labor costs and minimizing human error. According to a study from Smithers Pira, the global market for automated packaging systems is expected to grow at a CAGR of 11.9% from 2021 to 2026. This shift not only streamlines operations but also enhances product safety and extends shelf life through superior sealing technologies.

Employers considering an upgrade to automated wrapping machines should focus on selecting models that align with their production needs and scale. Investing in machinery equipped with smart technology can provide real-time data analytics, allowing businesses to optimize their wrapping processes and monitor performance metrics.

Tip: Always analyze your current packaging process before implementing automation. Identify the bottlenecks and evaluate how automation can specifically address those challenges. Regular maintenance of your wrapping machines is also essential to avoid unexpected downtimes and ensure consistent packaging quality.

The Environmental Impact of Using Plastic Wrapping Technology

The environmental impact of plastic wrapping technology has garnered significant attention in recent years, especially as industries seek sustainable alternatives to traditional packaging solutions. As the global market for biodegradable and bio-based plastic packaging materials expands, it is estimated that the market will reach $172.35 billion by 2033, growing from $156.98 billion in 2025, with a compound annual growth rate of 2.8%. This shift is primarily driven by heightened consumer awareness and increasing regulatory measures aimed at reducing plastic waste.

The European Union's updated regulations mandate that, starting in 2025, plastic bottles must contain at least 25% recycled material. This initiative not only highlights the importance of reusing existing materials but also encourages manufacturers to invest in innovative packaging solutions that minimize environmental footprints. Furthermore, the soluble packaging market is projected to grow from $3.97 billion in 2025 to $5.65 billion by 2032, reflecting the growing demand for environmentally friendly options. As companies pivot towards sustainable practices, the integration of biodegradable materials into packaging presents an opportunity to enhance both environmental sustainability and consumer appeal.

Key Features to Look for in Modern Packaging Machines

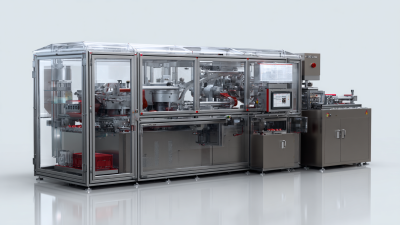

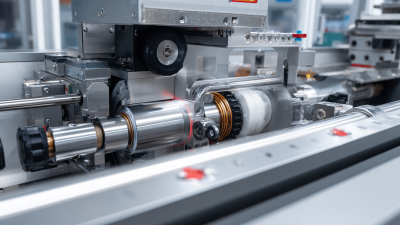

When considering modern plastic wrapping machines, there are several key features that significantly enhance packaging efficiency. Firstly, look for machines that offer adjustable sealing settings. This flexibility allows users to package products of varying sizes with precision, reducing material waste and ensuring a tight seal. Advanced temperature control systems are also crucial, as they ensure consistent performance, which is vital for preserving product integrity.

Another feature to consider is the machine's speed. High-speed wrapping machines can drastically increase output without compromising quality. Selecting a machine with a user-friendly interface can also streamline operations, making it easier for workers to operate the equipment effectively and reducing downtime.

Tips: When choosing a plastic wrapping machine, assess the maintenance requirements. Machines that are easier to maintain will save time and reduce long-term costs. Additionally, consider investing in multifunctional machines that can perform various packaging tasks, increasing versatility and further optimizing your production line.

Optimizing Production Lines with Advanced Wrapping Solutions

In today's fast-paced manufacturing environment, optimizing production lines is essential for achieving competitive advantage. Advanced plastic wrapping machines are at the forefront of this transformation, offering significant enhancements in both efficiency and flexibility. According to a report by Smithers Pira, the global market for industrial packaging is expected to reach $280 billion by 2025, with a projected growth rate of 4% annually. This surge is largely driven by the demand for faster processing times and reduced labor costs, which innovative wrapping solutions can effectively address.

These machines employ cutting-edge technology, such as automated wrapping and intelligent controls, which streamline the packaging process. The ability to quickly adjust to different product sizes and packaging materials enables manufacturers to reduce downtime and optimize their workflow. A study from the Packaging Machinery Manufacturers Institute indicates that companies utilizing advanced wrapping solutions can improve their packaging speed by up to 30%, significantly impacting overall production line performance. As businesses continue to adopt these technologies, the efficiency gains will contribute to sustained growth in the manufacturing sector.

Packaging Efficiency Improvement with Plastic Wrapping Machines

This chart illustrates the significant improvement in packaging efficiency due to the implementation of advanced plastic wrapping machines. The production line efficiency has increased from 120 to 250 units per hour, showcasing the transformative impact of these technologies.

Cost Savings Realized Through Efficient Plastic Packaging Systems

In the fast-paced world of modern manufacturing, the adoption of advanced plastic wrapping machines is proving to be a game-changer for businesses seeking to enhance their packaging efficiency. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2025, driven largely by innovations in packaging technology. Efficient plastic packaging systems not only optimize operational processes but also contribute significantly to cost savings. Industries utilizing these machines can reduce packaging material usage by up to 20%, translating to direct reductions in operational expenses.

Moreover, automated plastic wrapping systems streamline the packaging process, allowing for increased throughput without compromising quality. A case study from the Packaging Machinery Manufacturers Institute (PMMI) revealed that organizations implementing these machines experienced a 30% increase in production efficiency while simultaneously decreasing labor costs by 15%. Such advancements in packaging technology facilitate quicker product turnaround times and minimize waste, ensuring that companies remain competitive in an increasingly tight market landscape. As businesses continue to seek innovative solutions, it becomes evident that embracing efficient plastic packaging systems is not just an option but a necessity for long-term sustainability and profitability.

Unveiling the Future: How Plastic Wrapping Machines Are Revolutionizing Packaging Efficiency

| Parameter | Value | Notes |

|---|---|---|

| Average Cost Saving per Package | $0.05 | Due to reduced material usage |

| Increase in Packaging Speed | 30% | Compared to manual wrapping |

| Reduction in Waste | 25% | More efficient material usage |

| Labor Cost Reduction | 20% | Less manual intervention required |

| Return on Investment (ROI) | 12 months | Average for typical machinery |

| Energy Consumption Reduction | 15% | Modern machines are energy efficient |

Related Posts

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

How to Choose the Best Wrapping Machine by Understanding Key Technical Specifications and Features

-

Essential Checklist for Choosing the Best Stretch Wrapping Machine for Your Business

-

Ultimate Guide to Choosing the Best Packaging Machinery for Your Business

-

Emerging Trends in Food Packaging Technology 2025 Your Ultimate Guide to the Best Food Packing Machines

-

Challenges in Meeting Industry Standards for the Best Horizontal Wrapping Machine