Revolutionizing the Food Industry with Advanced Flow Wrapper Packaging Machines

The food industry is undergoing a significant transformation, largely driven by advancements in

packaging technology.

One of the most impactful innovations is the flow wrapper packaging machine,

which has revolutionized the way food products are packaged and preserved. According to a recent report by

ResearchAndMarkets, the global food packaging market is

projected to reach USD 500 billion by 2026, with flexible packaging

options, including flow wrappers, garnering a substantial share due to their efficiency and ability to

extend product shelf life. Flow wrapper machines provide several advantages, such as

speed, versatility, and reduced material waste, making them

indispensable in modern food processing. As consumer demand for

convenience, quality, and sustainability continues

to rise, embracing these advanced technologies will be crucial for food manufacturers aiming to

stay competitive in this fast-evolving industry.

The food industry is undergoing a significant transformation, largely driven by advancements in

packaging technology.

One of the most impactful innovations is the flow wrapper packaging machine,

which has revolutionized the way food products are packaged and preserved. According to a recent report by

ResearchAndMarkets, the global food packaging market is

projected to reach USD 500 billion by 2026, with flexible packaging

options, including flow wrappers, garnering a substantial share due to their efficiency and ability to

extend product shelf life. Flow wrapper machines provide several advantages, such as

speed, versatility, and reduced material waste, making them

indispensable in modern food processing. As consumer demand for

convenience, quality, and sustainability continues

to rise, embracing these advanced technologies will be crucial for food manufacturers aiming to

stay competitive in this fast-evolving industry.

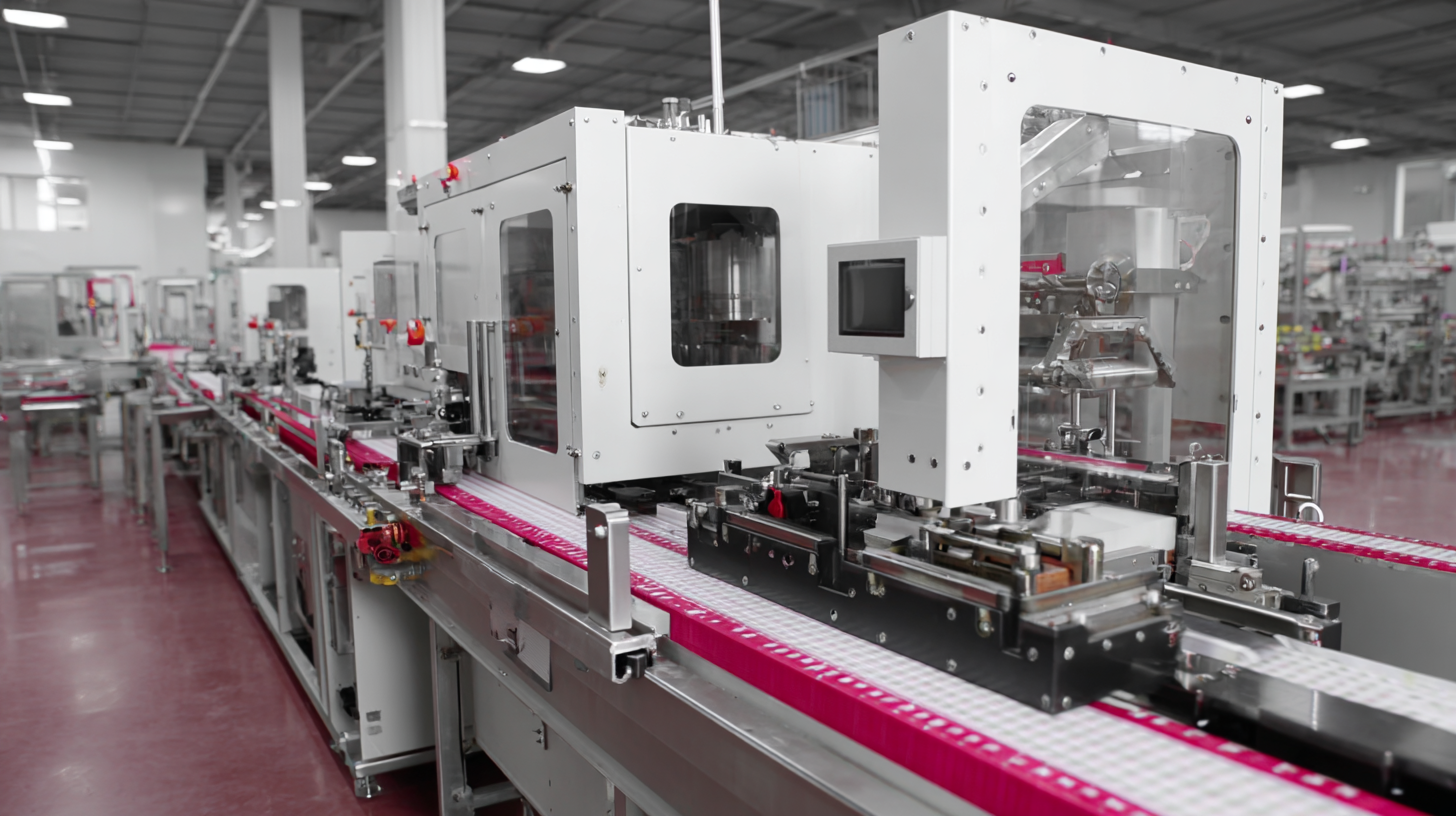

Understanding Advanced Flow Wrapper Technology in Food Packaging

Advanced flow wrapper technology is transforming food packaging by enhancing efficiency, maintaining quality, and extending shelf life. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $320 billion by 2024, with flow wrap technology accounting for a significant portion of this growth. This innovation enables manufacturers to produce packages that are not only aesthetically appealing but also functional, protecting food from external contaminants and ensuring freshness.

Advanced flow wrapper technology is transforming food packaging by enhancing efficiency, maintaining quality, and extending shelf life. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $320 billion by 2024, with flow wrap technology accounting for a significant portion of this growth. This innovation enables manufacturers to produce packages that are not only aesthetically appealing but also functional, protecting food from external contaminants and ensuring freshness.

Tips: To maximize the benefits of advanced flow wrappers, prioritize selecting materials that are suited for your specific product types. For instance, use high-barrier films for moisture-sensitive items to prevent spoilage, while transparent films can enhance product visibility on retail shelves.

Furthermore, advanced flow wrappers can be integrated with intelligent systems that monitor packaging processes in real time. This allows for adjustments on-the-fly, significantly reducing material waste and increasing operational efficiency. A study from MarketsandMarkets indicated that automation technologies in the packaging industry could lead to cost reductions of up to 30%. As the food industry increasingly embraces these technologies, brands that invest in advanced flow wrappers will likely gain a competitive advantage in delivering quality products to consumers.

Tips: Regularly evaluate your packaging machinery for maintenance and updates to ensure optimal performance. Staying current with technological advancements can significantly enhance your production capabilities.

Key Benefits of Using Flow Wrapper Machines in Food Production

The food industry is undergoing a significant transformation with the adoption of advanced flow wrapper packaging machines. These machines offer several key benefits that enhance food production processes. First and foremost, flow wrappers provide superior sealing capabilities, which helps to maintain the freshness and quality of food products. By effectively sealing various items—from snacks to frozen goods—these machines minimize air exposure, reducing spoilage and extending shelf life.

Additionally, flow wrapper machines are known for their efficiency and versatility. They can easily adapt to different product shapes and sizes, allowing manufacturers to package a wide range of items without significant downtime. This flexibility leads to increased productivity, enabling food producers to meet rising consumer demands quickly. Furthermore, the integration of automation and smart technology in these machines facilitates real-time monitoring and adjustments, which streamline operations and reduce labor costs. As a result, flow wrapper machines are revolutionizing the food packaging landscape, making it more efficient and reliable than ever before.

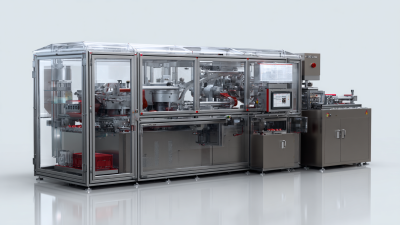

Choosing the Right Flow Wrapper for Your Food Packaging Needs

When it comes to food packaging, choosing the right flow wrapper is essential for enhancing product freshness and extending shelf life. With the global flexible packaging market projected to reach $300 billion by 2024, the importance of selecting a high-quality flow wrapper cannot be overstated. Key factors to consider include the machine's speed, reliability, and compatibility with various materials. According to a recent report from Smithers Pira, advanced flow wrapping technology can increase production efficiency by up to 25%, making it a vital investment for food manufacturers.

Tips for selecting the right flow wrapper include assessing your product specifications and packaging requirements. For instance, consider the size and shape of your food items, as well as the desired packaging material. Additionally, evaluate the machine's ease of operation and maintenance, as well as its adaptability to changing production needs. A well-chosen flow wrapper can significantly reduce packaging errors and waste, leading to improved overall efficiency.

Furthermore, stay informed about industry trends and technological advancements that may impact your packaging processes. The integration of smart technology in flow wrappers can enhance tracking and monitoring capabilities, allowing for real-time adjustments. This not only optimizes production but also ensures compliance with food safety regulations, ultimately benefiting your brand's reputation in the competitive food industry.

Flow Wrapper Packaging Machines Usage in the Food Industry

This chart illustrates the percentage of different food categories utilizing advanced flow wrapper packaging machines, highlighting their importance in modern food packaging solutions.

Best Practices for Implementing Flow Wrapper Machines in Your Operations

Implementing flow wrapper machines in food packaging operations requires careful planning and execution to maximize efficiency and product integrity.

First, it's essential to assess the specific needs of your production line, including the types of products being packaged and the desired output speed. By considering these factors, businesses can select the most suitable flow wrapper model that aligns with their production goals.

Additionally, training staff on the machine's operations and maintenance is crucial to ensure seamless integration into existing workflows.

Another best practice involves regularly evaluating the packaging materials used with flow wrappers. Choosing the right film can significantly impact product freshness and shelf life. It’s advisable to work closely with suppliers to find materials that not only preserve quality but also enhance visual appeal.

Conducting trial runs can help identify optimal settings and adjustments necessary for achieving the best packaging results. Lastly, incorporating regular maintenance schedules will prolong the life of the machinery, prevent unexpected breakdowns, and maintain consistent productivity levels.

Future Trends in Flow Wrapper Packaging for the Food Industry

The future of flow wrapper packaging in the food industry is poised for remarkable transformation, driven by technological advancements and changing consumer preferences. According to a recent report by Markets and Markets, the global food packaging market is expected to reach $600 billion by 2024, with flow wrappers emerging as a key segment. These machines not only enhance shelf life but also reduce food wastage, aligning with the industry's sustainability goals. Innovations such as smart packaging and automation are set to redefine operational efficiency, offering real-time data on inventory and consumer trends.

Tips: When considering flow wrapper options, prioritize machines with energy-saving features. This not only improves your bottom line but also contributes to a more sustainable production process. Moreover, integrating RFID technology can optimize tracking and reduce errors in packaging processes.

As the food industry looks ahead, customization in packaging will become more prevalent. With consumer demand for personalized products on the rise, manufacturers are adopting flexible flow wrapper systems that can easily adapt to different packaging sizes and materials. A recent study by Grand View Research predicts a CAGR of 4.5% in custom food packaging solutions, highlighting the necessity for adaptability in packaging machinery to meet these evolving market needs.

Revolutionizing the Food Industry with Advanced Flow Wrapper Packaging Machines - Future Trends in Flow Wrapper Packaging for the Food Industry

| Packaging Type | Material Used | Production Speed (units/min) | Automation Level | Sustainability Features |

|---|---|---|---|---|

| Flow Wrap | Biodegradable Film | 120 | Fully Automated | Recyclable Materials |

| Vertical Form Fill Seal | Plastic Film | 100 | Semi-Automated | Reduced Energy Consumption |

| Horizontal Flow Wrapper | Aluminum Foil | 150 | Fully Automated | Biodegradable Options |

| Shrink Wrap | Polyethylene | 90 | Manual | Low Waste Production |

Related Posts

-

Discover World Class Manufacturing with the Best Flow Wrap Machine from China

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

7 Compelling Reasons Your Business Needs an Automatic Packaging Machine Today

-

Flow Wrap Machines: An In-Depth Comparison of Features, Costs, and Performance

-

How to Choose the Right Horizontal Wrapping Machine for Your Business Needs