Top Tips for Choosing a Flow Wrapper Packaging Machine?

Choosing the right flow wrapper packaging machine is crucial for efficiency. John Smith, a leading expert in packaging technology, once said, “The right machine can elevate your production.” This statement resonates with many manufacturers facing today's challenges.

As the demand for versatile packaging solutions grows, knowing what to look for becomes vital. A flow wrapper packaging machine ensures products are sealed and protected efficiently. Whether you are packaging snacks, bakery items, or medical supplies, the right machine can make all the difference.

However, many companies rush this decision. They may overlook important features like speed, durability, and ease of use. Understanding these elements can prevent costly mistakes. Reflecting on your production needs is essential. Choosing a flow wrapper requires careful thought, as the wrong machine could hinder operations. Aim for clarity in your requirements before making a choice.

Understanding Flow Wrapper Packaging Machines

When it comes to flow wrapper packaging machines, understanding their features is crucial. These machines create tight seals around products, ensuring freshness and protection. They can handle various items, from snacks to medical supplies. A good flow wrapper uses high-quality materials, which affects durability and performance.

Choosing the right machine involves considering your specific needs. For example, the machine's speed matters if you have high production demands. Also, think about the size of the products. Adjustability is important; not all items are the same. Finding a machine that fits your range requires research and careful thought.

Maintenance is another factor that should not be overlooked. Regular checks can prevent costly downtime. However, some might underestimate how often maintenance is needed. It's easy to get caught up in production, but neglecting upkeep can lead to issues later. Reflecting on these factors ensures you make a more informed choice.

Identifying Your Packaging Needs and Requirements

Choosing the right flow wrapper packaging machine starts with understanding your specific packaging needs. Analyze the type of products you wish to package. Are they fragile items like baked goods? Or are they robust products like frozen foods? The nature of your goods significantly impacts the machine you need.

According to industry reports, around 45% of packaging failures stem from mismatched equipment. This can cause product damage and increased waste. Your chosen machine must effectively handle your products' speed, dimensions, and weight. Additionally, consider the volume of production. Are you running small batches or large-scale operations? Packaging systems vary, with some designed for high efficiency and others suited for versatility.

Don't overlook the flexibility of packaging materials either. A machine that accommodates various materials can provide more options. Remember, some companies must compromise on features due to budget constraints. This can lead to operational challenges later. Evaluate long-term growth. The right flow wrapper should adapt to future needs, not just current demands.

Top Tips for Choosing a Flow Wrapper Packaging Machine

Evaluating Key Features and Specifications

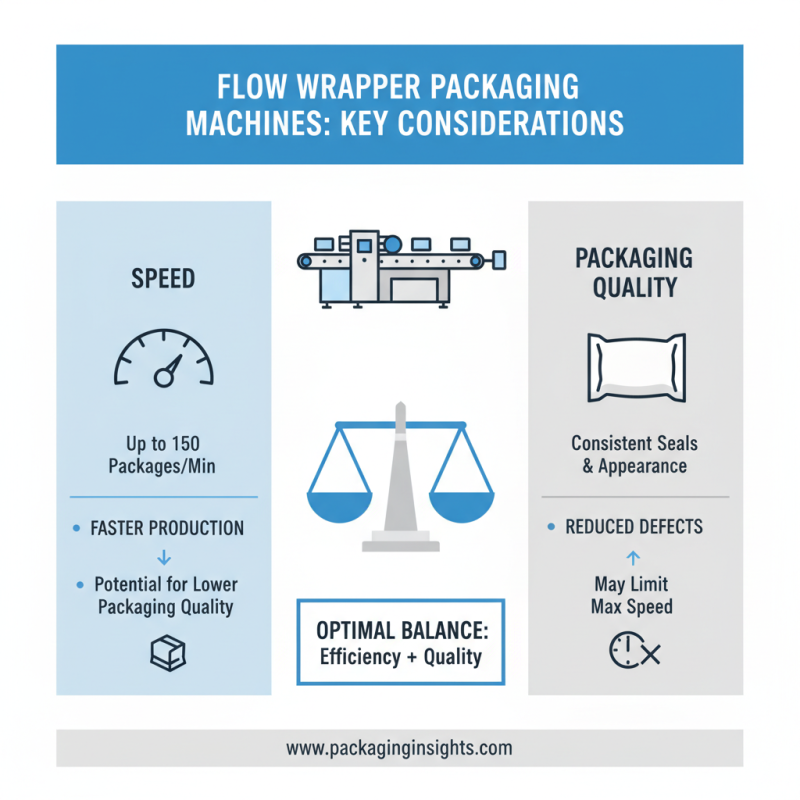

When evaluating flow wrapper packaging machines, key features and specifications play a critical role. Consider the speed of the machine. Some models can achieve up to 150 packages per minute. However, higher speed can compromise the packaging quality. Balancing speed with operational quality is essential.

Another important aspect is the machine’s versatility. It should handle different types of products, from snacks to pharmaceuticals. Research shows that 70% of packaging waste stems from improperly sized packages. Thus, adjustability is vital to maintaining efficiency.

Make sure to check the technology used in the machines. Some feature advanced controls, ensuring precise sealing and consistent packaging. However, less sophisticated options may save money upfront yet often lead to higher long-term costs due to maintenance issues. Evaluate your production needs carefully, as investing in quality technology can yield significant returns.

Considering Budget and Cost of Ownership

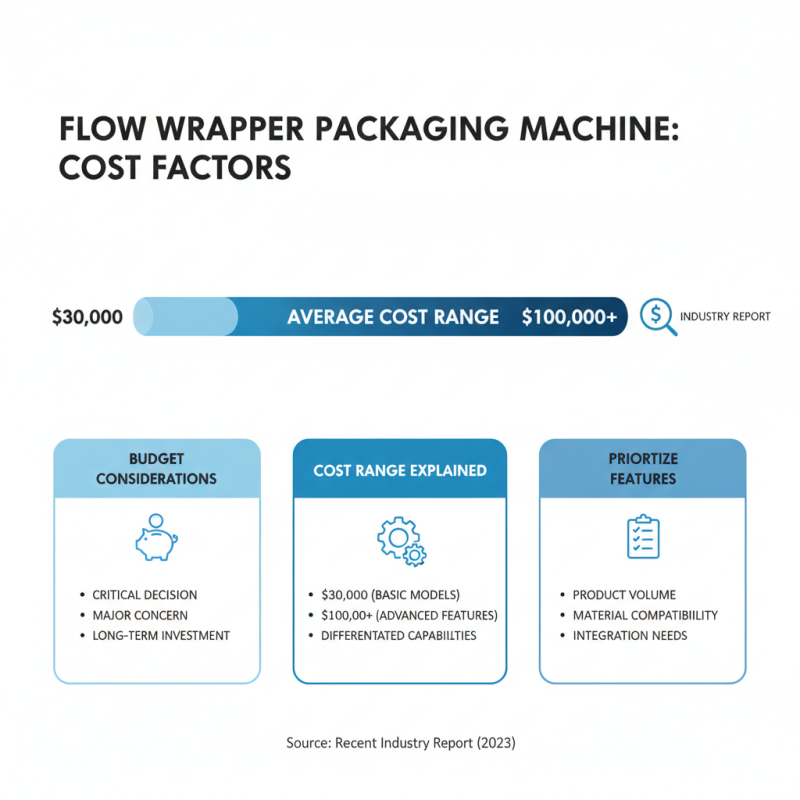

Choosing a flow wrapper packaging machine is a critical decision for manufacturers. Budget is a major concern. According to a recent industry report, the average cost of a flow wrapper ranges from $30,000 to $100,000. This wide range reflects different features and capabilities. It's essential to prioritize what features matter most for your product.

Cost of ownership is another key point. Not just the initial price matters. Maintenance and operation costs can add up. A study showed that ongoing maintenance can account for 15-20% of the machine's purchase price annually. This is significant. Assessing energy efficiency is also crucial. Machines with better energy ratings can reduce costs over time.

Operator training is often overlooked. It can require additional investment. Poor training may lead to mistakes, increasing downtime. Downtime itself can significantly impact productivity. A survey indicated that unplanned downtimes can cost manufacturers up to $250,000 annually. Therefore, invest wisely, balance upfront costs with future expenses, and ensure thorough operator training.

Researching Manufacturers and Customer Reviews

When researching flow wrapper packaging machines, customer reviews are invaluable. A recent report highlights that over 70% of buyers rely on online reviews before making a purchase. Feedback provides insight into a machine's performance, reliability, and ongoing support. Observing both positive and negative reviews can help in making a more informed decision.

It's not just about praising features. Some users mention issues with maintenance and the learning curve involved. For instance, one customer noted, "It took weeks to adequately train staff." This points to the potential need for robust training programs. Additionally, understanding the customer service quality is crucial. A survey indicated that 55% of users faced challenges with technical support.

Comparing multiple manufacturers helps identify the most reliable options. Reports suggest that companies with higher customer satisfaction ratings often invest more in training and support. It is a key indicator of their commitment to quality. Look for those who engage actively with customers, addressing concerns effectively. This dynamic may indicate better long-term satisfaction.

Related Posts

-

Exploring Cost Effective Alternatives to the Best Vertical Packaging Machine for Your Business

-

Unlocking the Technical Specifications of the Best Flow Wrap Machine for Global Procurement Needs

-

7 Compelling Reasons Your Business Needs an Automatic Packaging Machine Today

-

Revolutionizing the Food Industry with Advanced Flow Wrapper Packaging Machines

-

Top 10 Flow Wrapper Packaging Machines for Efficient and Secure Packaging Solutions

-

What is the Best Flow Wrapper Packaging Machine for 2026?