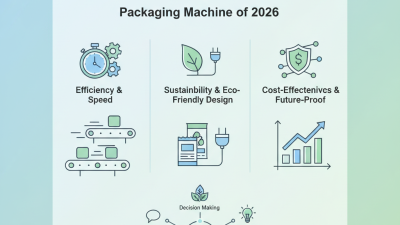

2026 Top Flow Wrap Machine Innovations and Trends to Watch?

As the packaging industry evolves, the flow wrap machine plays a crucial role in this transformation. Experts predict that the global flow wrap machine market will grow at a compound annual growth rate (CAGR) of 5.3% by 2027, according to Market Research Future. This growth stems from increasing demand for efficient packaging solutions that enhance product shelf life and reduce waste.

Industry specialist Mark Thompson emphasizes, "The flow wrap machine is at the forefront of innovation, adapting to changing consumer needs." New technologies in this field are refining speed and precision. However, the challenge lies in balancing efficiency with sustainability. Companies face pressure to reduce packaging waste while maintaining high productivity levels.

Innovations like smart sensors and improved material usage are promising yet need thorough evaluation. The industry must continuously adapt to meet these expectations. Understanding the latest trends is vital for companies aiming to thrive in this competitive landscape.

Emerging Technologies in Flow Wrap Machines for 2026

As we look ahead to 2026, flow wrap machines are poised for remarkable innovations. Emerging technologies are shaping their design and efficiency. One notable trend is the integration of smart sensors. These sensors monitor performance in real-time, identifying bottlenecks and optimizing workflows. A seamless connection to IoT devices could transform data analysis. Yet, the challenge lies in ensuring systems are secure and efficient.

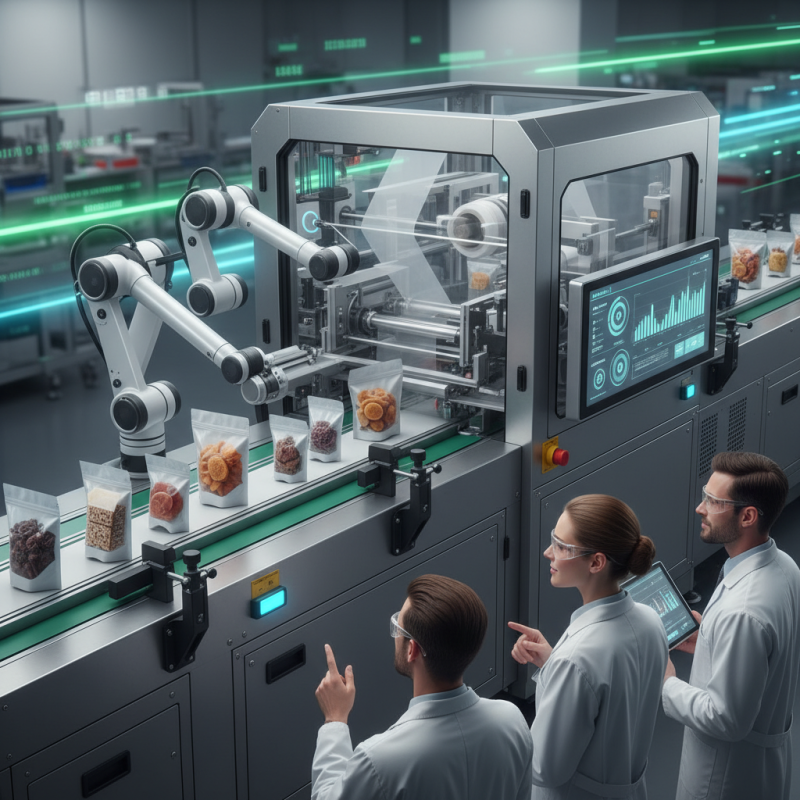

Sustainability is another key focus. Manufacturers are exploring biodegradable packaging materials. Innovations aim to reduce waste and improve recyclability. However, finding materials that maintain product integrity while being eco-friendly remains a complex task. Additionally, automation will redefine operations. Advanced robotics may streamline the packaging process, increasing speed and precision. Training staff to adapt to these changes is critical, yet it raises concerns about skill gaps.

Moreover, customization is gaining traction. Machines that can switch between products with minimal downtime are essential. This flexibility could enhance competitiveness. Companies may struggle to balance innovation and cost, leading to tough choices. Each advancement brings opportunities and potential hurdles that must be addressed thoughtfully. The path forward is filled with excitement and challenges alike.

2026 Top Flow Wrap Machine Innovations and Trends to Watch

| Innovation Trend | Description | Potential Impact | Expected Adoption Year |

|---|---|---|---|

| AI-Driven Automation | Integration of AI to enhance efficiency and predictive maintenance. | Improved productivity and reduced downtime. | 2026 |

| Eco-Friendly Materials | Use of biodegradable and sustainable packaging materials. | Enhanced brand image and compliance with regulations. | 2025 |

| Smart Connectivity | Machines equipped with IoT for real-time data sharing and analysis. | Enhanced monitoring and decision-making capabilities. | 2026 |

| Robotic Integration | Collaboration with robotics for enhanced operational capabilities. | Improved precision and reduced labor costs. | 2026 |

| Advanced Film Technologies | Development of thinner, stronger films that improve packaging efficiency. | Reduced material costs and environmental footprint. | 2025 |

Sustainability Trends in Packaging Solutions: A Focus on Flow Wrapping

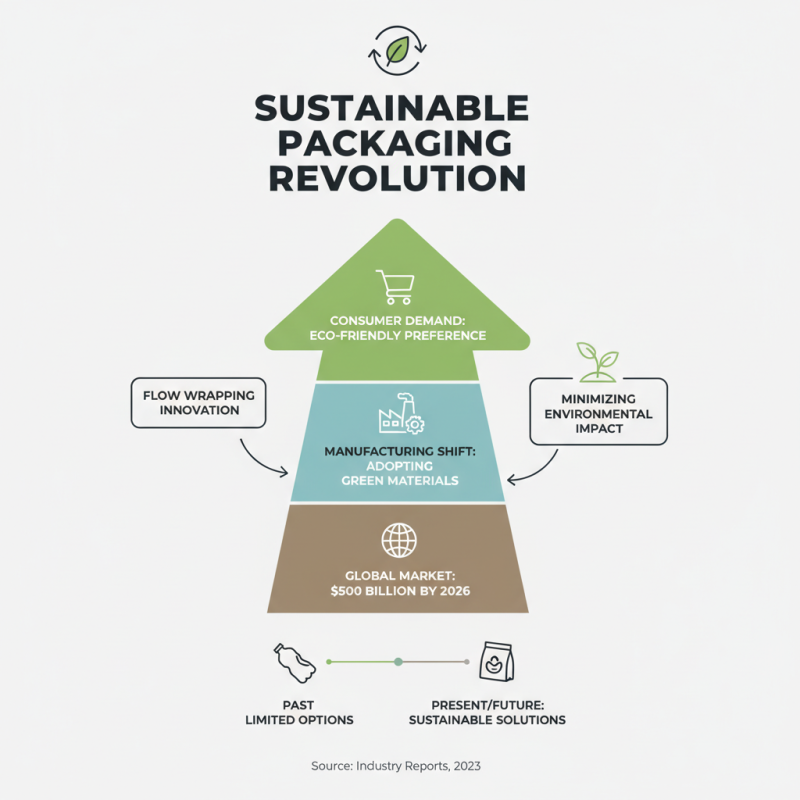

Sustainability is reshaping packaging, particularly in flow wrapping. The global sustainable packaging market is projected to reach $500 billion by 2026, with a significant focus on eco-friendly materials. In recent years, consumer demand has shifted. Many now prefer packaging that minimizes environmental impact. That’s a trend manufacturers cannot ignore.

Biodegradable films and recyclable materials are gaining traction. Research shows that 73% of consumers are willing to pay more for sustainable packaging. However, the technology isn't perfect yet. Many manufacturers struggle to balance performance and environmental responsibility. For instance, some biodegradable options lack durability. This can lead to product spoilage and wasted resources.

Adopting sustainable practices requires introspection. Companies must evaluate their current processes critically. Are conventional materials out of touch with consumer expectations? The industry must innovate while addressing these challenges. Embracing greener practices is key. But it demands investment and a willingness to experiment with new solutions.

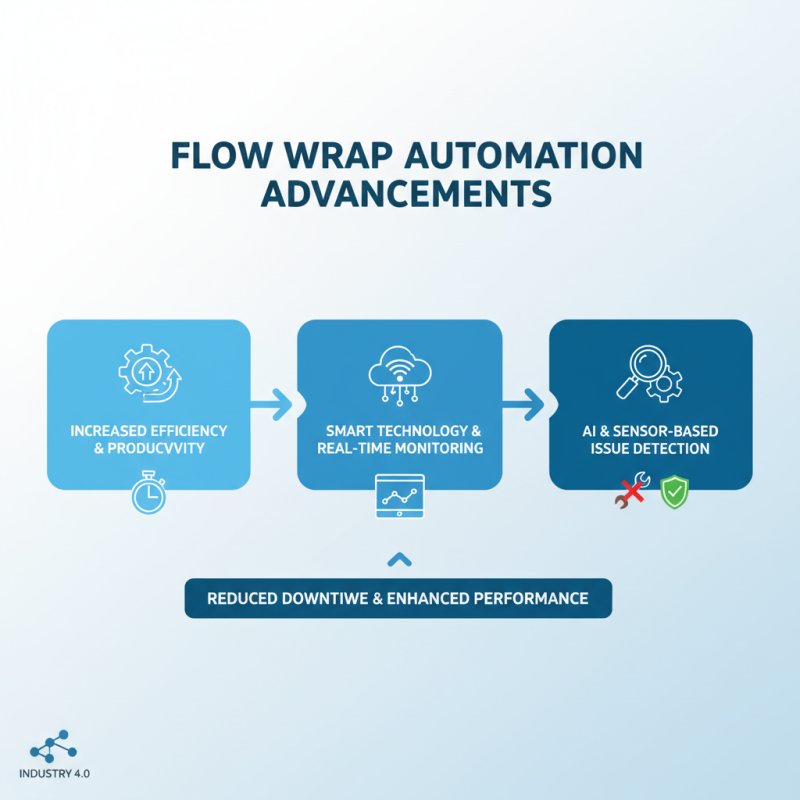

Automation Advancements: Enhancing Efficiency in Flow Wrap Machines

The flow wrap machine industry is experiencing significant automation advancements. These innovations are aimed at boosting efficiency and productivity. Smart technologies are now integrated into these machines, enabling real-time monitoring. This helps reduce downtime and improve overall performance. With sensors and AI, flow wrap machines can detect issues before they escalate.

Automated systems enhance the precision of packaging. This leads to fewer errors and reduced waste. Operators can manage multiple machines from a single interface. However, this reliance on technology can create challenges. Training staff to use advanced systems is essential. There also remains a risk of equipment failure, which could impact production.

These advancements focus on speed and adaptability. Machines can quickly adjust to different product sizes and packaging materials. Yet, over-automation might lead to some loss of craftsmanship. A balance must be struck to maintain quality while benefiting from efficiency. Continuous evaluation of these trends will be crucial as the industry evolves.

Consumer Preferences Shaping the Future of Flow Wrap Packaging

As the flow wrap packaging industry evolves, consumer preferences are paramount in shaping future innovations. Recent studies indicate that 78% of consumers prioritize sustainable packaging. This trend pushes manufacturers to adopt eco-friendly materials in their flow wrap machines. Consumers will increasingly demand solutions that reduce waste and carbon footprints.

Moreover, a report from Packaging Innovations highlights personalization as a growing interest. Around 65% of consumers prefer products that reflect their individuality. This preference drives the need for flexible and adaptable flow wrap machinery. The ability to customize packaging sizes and designs will become crucial in meeting these expectations.

However, meeting these demands presents challenges. Many manufacturers struggle with balancing cost and sustainability. In 2022, a significant percentage reported that switching to greener materials increased production costs. The industry must innovate not just for aesthetics but also for efficiency. Consumers expect more, and the pressure is on.

2026 Flow Wrap Machine Innovations and Trends

Market Predictions: Growth and Innovations in Flow Wrap Machinery

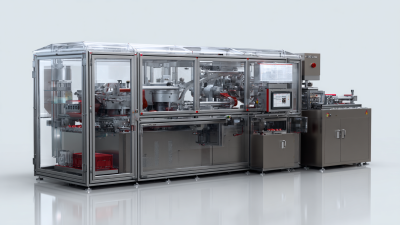

The flow wrap machinery market is set for significant growth. According to industry reports, this segment is expected to expand at a compound annual growth rate (CAGR) of 4.5% by 2026. This growth is fueled by increasing demand for efficient packaging solutions across various sectors, notably in food and pharmaceuticals.

Innovations are emerging rapidly. Automation and smart technologies are reshaping flow wrap machines. These advancements enhance efficiency and minimize waste. Reports highlight a shift towards sustainable materials in flow wrapping. Consumers increasingly prefer eco-friendly packaging options. This shift creates new opportunities for manufacturers to innovate.

Tips: Consider integrating smart technology into your packaging line. Monitor performance metrics regularly. This can lead to cost savings and better resource management. Explore eco-friendly materials for your packaging needs. Many options are available that meet both sustainability goals and consumer demands. Balancing innovation with practicality can be a challenge. Regular evaluation of your processes ensures they meet market trends while remaining efficient.

Related Posts

-

Exploring Innovative Alternatives to the Best Flow Wrapper Packaging Machines

-

Maximizing Efficiency with Advanced Wrapping Machine Solutions

-

Discover World Class Manufacturing with the Best Flow Wrap Machine from China

-

Revolutionizing the Food Industry with Advanced Flow Wrapper Packaging Machines

-

What is the Best Flow Wrapper Packaging Machine for 2026?

-

How to Choose the Best Flow Wrap Machine for Your Packaging Needs in 2025