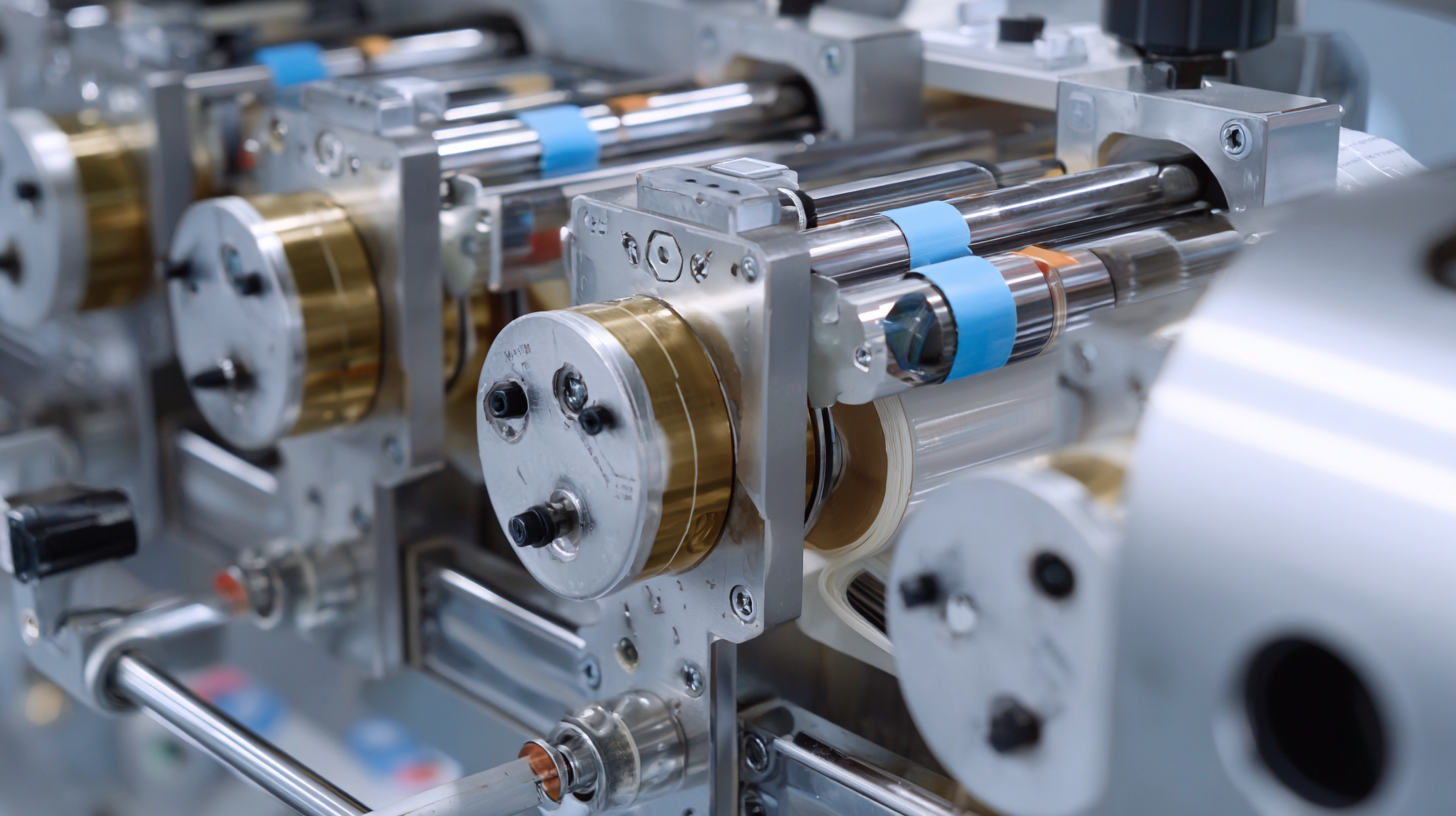

Top 5 Global Certifications You Need for the Best Pouch Machine in 2023

In today's rapidly evolving packaging industry, the demand for pouch machines has surged, driven by the growing preference for flexible packaging solutions. According to a recent report by Smithers Pira, the flexible packaging market is expected to reach a value of over $300 billion by 2025, with pouches accounting for a significant share due to their convenience and cost-effectiveness. As manufacturers seek to enhance productivity and meet diverse consumer needs, acquiring global certifications for pouch machines has become essential. These certifications not only ensure compliance with international standards but also signify a commitment to quality and innovation in the highly competitive market. In 2023, staying ahead of the curve requires understanding which certifications are most valuable, thus positioning your operation for success in an industry poised for continuous growth.

Advantages of Comprehensive After-Sales Service for Pouch Machines

In the competitive market of pouch packaging machines, the importance of comprehensive after-sales service cannot be overstated. A recent report by Smithers Pira indicates that after-sales support significantly increases customer satisfaction and loyalty, with 85% of manufacturers noting that excellent service enhances brand reputation. Furthermore, 76%% of companies report an increase in repeat purchases when robust after-sales services are provided, directly impacting profitability and market share.

Investing in comprehensive after-sales service not only ensures that the pouch machines operate optimally but also minimizes downtime. According to a study from Technavio, manufacturers who offer quick response times in service lead to a 30% reduction in machine downtime, which translates into substantial cost savings and improved operational efficiencies. Moreover, training and support offered as part of after-sales service can empower users to maximize the capabilities of their machines, allowing for better efficiency and innovation in packaging processes. With the growing demand for sustainable packaging solutions, having a reliable service framework becomes a critical differentiator in the industry.

Understanding Maintenance Costs: Budgeting for Pouch Machine Ownership

When considering the ownership of a pouch machine, understanding the maintenance costs is crucial for effective budgeting. The total cost of ownership (TCO) includes not only the initial purchase price but also operational and maintenance expenses that can accumulate over the machine’s life cycle. For businesses, this means accounting for costs such as routine servicing, parts replacement, and potential downtime which could impact productivity. A realistic budgeting approach must factor in these variables to ensure sustainability in operations.

One effective budgeting method that can be applied to pouch machine ownership is zero-based budgeting (ZBB). This process requires companies to start from a "zero base" each budgeting period, scrutinizing all expenses instead of just adjusting previous budgets. By reassessing every cost associated with the pouch machine, businesses can better identify areas for savings and optimize their overall expenditures. With the construction industry's shift towards efficiency and sustainability, adopting proactive budgeting approaches like ZBB could lead to significant cost benefits and improved operational effectiveness in machinery ownership.

Key Certifications That Enhance Pouch Machine Performance

In the competitive landscape of pouch manufacturing, obtaining the right certifications is crucial for enhancing machine performance and ensuring compliance with industry standards. One of the most vital certifications is ISO 9001, which focuses on quality management systems. This certification not only helps manufacturers streamline their processes but also ensures that the pouch machines are built to meet customer expectations consistently, fostering trust and brand loyalty.

Another key certification that significantly impacts pouch machine performance is CE marking. This certification indicates that the equipment meets European standards for safety and environmental protection. By adhering to these norms, manufacturers can enhance the reliability of their machines while also expanding their market reach within Europe. Additionally, the HACCP certification is essential for machines used in food packaging. It assures that the manufacturing process adheres to strict safety protocols, mitigating risks that could compromise product quality and consumer health. Together, these certifications empower manufacturers to optimize their pouch machines, ultimately driving productivity and enhancing overall performance in 2023.

Maximizing Efficiency with Quality Assurance in Pouch Packaging

In the realm of pouch packaging, quality assurance is paramount to maximizing efficiency. According to a report by Freedonia Group, the global market for flexible packaging has been projected to reach $248 billion by 2025, with pouches playing a crucial role in this growth due to their versatility and shelf appeal. To harness this potential, manufacturers must prioritize certifications that ensure both product quality and operational efficiency.

In the realm of pouch packaging, quality assurance is paramount to maximizing efficiency. According to a report by Freedonia Group, the global market for flexible packaging has been projected to reach $248 billion by 2025, with pouches playing a crucial role in this growth due to their versatility and shelf appeal. To harness this potential, manufacturers must prioritize certifications that ensure both product quality and operational efficiency.

For instance, achieving ISO 9001 certification can significantly enhance a company’s manufacturing processes by focusing on continuous improvement and customer satisfaction. This standard provides a framework that helps organizations streamline their operations, leading to reduced waste and increased productivity. In addition, GFSI (Global Food Safety Initiative) certifications address safety standards specific to food-grade pouch applications, ensuring that products meet rigorous health regulations. A report from Smithers Pira indicates that food pouches with such certifications not only instill consumer confidence but also reduce contamination risks, thereby optimizing both quality and efficiency throughout the supply chain.

Preparing for Common Repairs: What Every Pouch Machine Owner Should Know

When owning a pouch machine, understanding common repairs is crucial to maintaining operational efficiency. One common issue faced by pouch machine owners is the failure of sealing elements, which can lead to product leakage. According to industry reports, around 20% of machine downtime is linked to seal-related failures. Regularly checking and replacing worn sealing parts can drastically reduce downtime and improve productivity.

Tips: Always keep a set of replacement sealing materials on hand, and schedule routine maintenance checks every six months. This proactive approach not only extends the life of your machine but also enhances the quality of your packaging.

Another critical area of machine maintenance involves the handling of software updates and troubleshooting minor electronic issues. It's essential to stay informed about the software that runs your pouch machine, as outdated systems may cause operational glitches. Research indicates that machine operators who receive ongoing training in software management experience 30% fewer operational disruptions.

Another critical area of machine maintenance involves the handling of software updates and troubleshooting minor electronic issues. It's essential to stay informed about the software that runs your pouch machine, as outdated systems may cause operational glitches. Research indicates that machine operators who receive ongoing training in software management experience 30% fewer operational disruptions.

Tips: Invest in professional development by attending workshops and training sessions on new machine technologies. Additionally, establish a troubleshooting guide specific to your pouch machine model to assist with common electronic issues, ensuring you can resolve minor problems swiftly and effectively.