Top 10 Stretch Wrapping Machines for Efficient Packaging Solutions

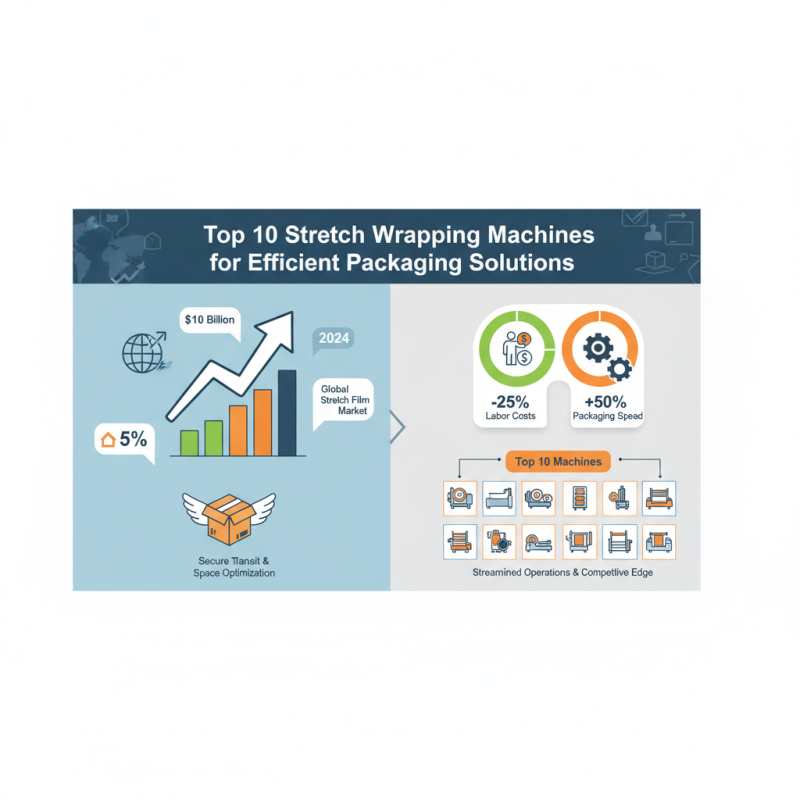

In the rapidly evolving landscape of packaging technology, the importance of efficiency and innovation cannot be overstated. According to a report by Smithers Pira, the global stretch film market is projected to reach over $10 billion by 2024, highlighting the critical role of stretch wrapping machines in modern logistics and supply chain operations. These machines are essential for ensuring products are securely packaged, minimizing damage during transit, and optimizing space utilization in warehouses.

As businesses strive to enhance their packaging processes, the demand for reliable and high-performance stretch wrapping machines has surged. Recent industry studies indicate that efficient packaging can lead to significant cost savings and improved operational efficiency. Notably, companies that implement automated packaging solutions experience a reduction in labor costs by up to 25%, while also increasing packaging speed by approximately 50%. Thus, identifying the top stretch wrapping machines available on the market becomes imperative for organizations looking to streamline their packaging operations and maintain a competitive edge.

Overview of Stretch Wrapping Machines and Their Importance in Packaging

Stretch wrapping machines are pivotal in modern packaging operations, significantly enhancing efficiency and protecting products during transportation and storage. According to a report by the Freedonia Group, the demand for packaging machinery, which includes stretch wrappers, is projected to reach $18 billion by 2025. This growth is driven by the need for improved productivity and cost-effective solutions in various industries such as food and beverage, consumer goods, and pharmaceuticals. Stretch wrapping machines not only facilitate faster packaging processes but also minimize product damage through effective stabilization and containment.

The importance of stretch wrapping technology can be underscored by its role in reducing packaging material waste and shrinkage. Research from PMMI suggests that automated stretch wrapping solutions can decrease up to 30% of packaging materials required, translating into both environmental and economic benefits. Furthermore, these machines enable businesses to streamline their operations, offering consistency and reliability in the packaging process that manual methods cannot achieve. As industries continue to evolve, investing in advanced stretch wrapping machines is becoming increasingly crucial for maximizing efficiency and maintaining competitive advantage in the marketplace.

Top 10 Stretch Wrapping Machines for Efficient Packaging Solutions

| Machine Model | Film Type | Wrapping Speed | Max Load Capacity | Power Consumption | Dimensions |

|---|---|---|---|---|---|

| SWM-200 | Cast Film | 30 RPM | 1500 kg | 1.5 kW | 1500 x 1200 x 2500 mm |

| SWM-300 | Monolayer Film | 35 RPM | 2000 kg | 2.0 kW | 1600 x 1300 x 2600 mm |

| SWM-400 | Stretch Film | 40 RPM | 2500 kg | 2.5 kW | 1700 x 1400 x 2800 mm |

| SWM-500 | Pre-Stretch Film | 45 RPM | 3000 kg | 3.0 kW | 1800 x 1500 x 3000 mm |

| SWM-600 | Crosslink Film | 50 RPM | 3500 kg | 3.5 kW | 1900 x 1600 x 3200 mm |

| SWM-700 | Biodegradable Film | 55 RPM | 4000 kg | 4.0 kW | 2000 x 1700 x 3400 mm |

| SWM-800 | PVC Film | 60 RPM | 4500 kg | 4.5 kW | 2100 x 1800 x 3600 mm |

| SWM-900 | LLDPE Film | 65 RPM | 5000 kg | 5.0 kW | 2200 x 1900 x 3800 mm |

| SWM-1000 | Hybrid Film | 70 RPM | 6000 kg | 6.0 kW | 2300 x 2000 x 4000 mm |

Key Features to Consider When Choosing a Stretch Wrapping Machine

When selecting a stretch wrapping machine, several key features should be prioritized to ensure you choose a solution that meets your packaging needs.

Firstly, consider the machine’s loading capacity and speed. A machine with a higher load capacity is essential for businesses dealing with various product weights and sizes. Additionally, the wrapping speed plays a crucial role in productivity; a faster machine can significantly reduce downtime and improve workflow efficiency.

Another important aspect is the type of stretch film compatibility. Not all machines work well with every stretch film type; thus, evaluating the type of pallets or products being wrapped is essential. Look for machines that offer flexibility in film choices to accommodate different packaging requirements.

Features such as adjustable tension controls allow for optimal film usage and can help reduce material costs while ensuring product protection during transportation.

Finally, consider automation features, as fully or semi-automated systems can enhance operational efficiency and minimize manual labor, providing a more streamlined packaging process.

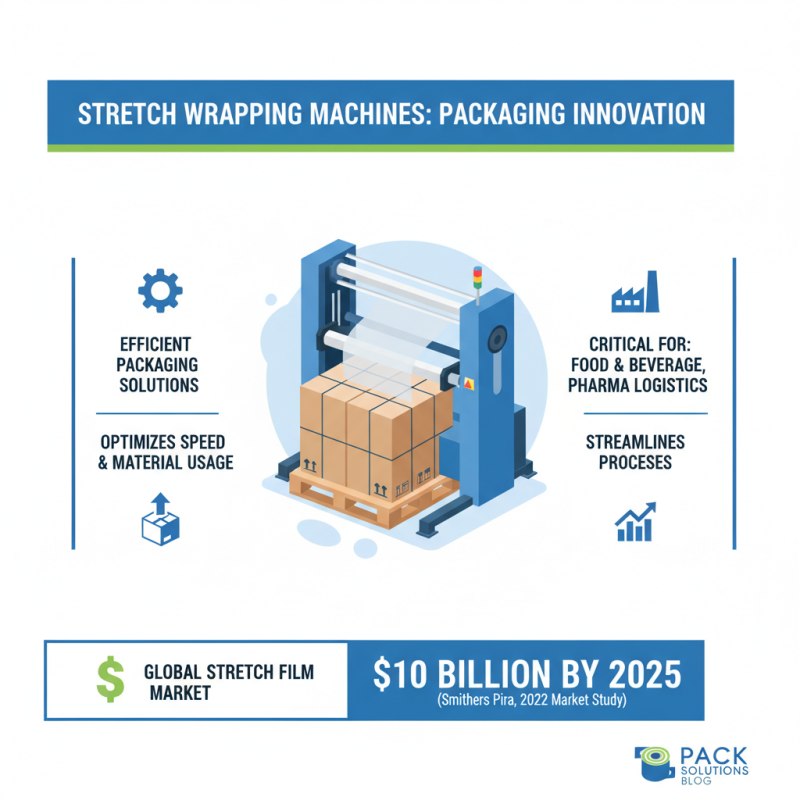

Top 10 Stretch Wrapping Machines: A Comprehensive Review

In recent years, the demand for efficient packaging solutions has driven significant advancements in the design and functionality of stretch wrapping machines. A comprehensive review reveals that these machines provide essential support to industries such as food and beverage, pharmaceuticals, and logistics, where optimizing packaging speed and material usage is critical. According to a 2022 market study by Smithers Pira, the global stretch film market is set to reach $10 billion by 2025, highlighting the growing reliance on these innovative machines to streamline packaging processes.

The efficiency of stretch wrapping machines is demonstrated through their ability to increase operational throughput while minimizing film usage. Industry reports indicate that automated stretch wrappers can boost productivity by up to 30% compared to manual wrapping methods. Additionally, advancements in technology have led to machines that integrate IoT capabilities, allowing for real-time monitoring and data analysis, which facilitates better decision-making regarding packaging operations. As companies continue to seek cost-effective and sustainable solutions, investing in high-quality stretch wrapping machines becomes a strategic move to enhance supply chain efficiency.

Comparative Analysis of the Best Stretch Wrapping Machines

In the realm of packaging solutions, stretch wrapping machines have emerged as essential tools for enhancing efficiency and securing products during shipping and storage. A comparative analysis of the leading stretch wrapping machines reveals key differences in performance, technology, and user adaptability that can significantly impact operational efficiency. According to a recent industry report by Smithers, the global market for stretch wrapping equipment is projected to grow at a compound annual growth rate (CAGR) of 5.1% through 2027, underscoring the increasing reliance on automated solutions for packaging processes.

The latest models of stretch wrapping machines are equipped with advanced features such as automated film cutting, adjustable tension settings, and enhanced film pre-stretch capabilities. These improvements not only reduce film usage by up to 30% but also ensure uniformity in load security, which is critical in preventing product damage. The material cost savings combined with increased wrapping speeds—reported at an average of 25 loads per hour—underscore the economic advantages of investing in high-quality equipment. Furthermore, user-friendly interfaces and programmable presets allow for rapid adjustments, accommodating various packaging needs with minimal downtime, a critical factor in modern production environments.

Overall, when evaluating stretch wrapping machines, it is essential to consider factors such as load stability, operational speed, and compatibility with existing workflow systems. The integration of IoT and smart technology in packaging machinery is further propelling the industry forward, offering real-time data analytics for better decision-making and enhanced tracking of supply chain logistics. The right machine can not only streamline operations but also contribute to a more sustainable packaging process by minimizing waste and maximizing efficiency.

Future Trends in Stretch Wrapping Technology and Packaging Solutions

As the packaging industry evolves, future trends in stretch wrapping technology focus on enhancing efficiency and sustainability. Recent advancements are steering toward automation and smart technologies that allow for real-time monitoring and adjustment of packaging processes. With features like IoT integration and machine learning, these systems can predict maintenance needs, optimize material usage, and reduce downtime. This not only streamlines operations but also significantly reduces overhead costs for businesses seeking to improve their packaging efficiency.

Moreover, sustainability is becoming increasingly paramount, with manufacturers prioritizing eco-friendly materials for stretch film and packaging. Innovations such as biodegradable stretch films and recyclable packaging alternatives are gaining traction, helping companies meet their environmental responsibility goals. These trends signify a shift toward reducing waste and promoting a circular economy, where packaging solutions not only protect products but also minimize the ecological footprint. The integration of these technologies signals a promising future for the stretch wrapping industry, aimed at supporting businesses in adapting to a more sustainable and efficient operational framework.

Related Posts

-

Essential Checklist for Choosing the Best Stretch Wrapping Machine for Your Business

-

How to Choose the Right Filling Machine for Your Production Needs

-

7 Compelling Reasons Your Business Needs an Automatic Packaging Machine Today

-

Flow Wrap Machines: An In-Depth Comparison of Features, Costs, and Performance

-

2025 Top 5 Automatic Packaging Machines Revolutionizing Efficiency and Productivity

-

Exploring the Unique Features and Applications of the Best Form Fill Seal Machines: A Complete Guide